Advanced 3D Printing Techniques for Soluble Supports

What’s the Big Deal with Soluble Supports, Anyway?

Alright, let’s get real. We’ve all been there: you’re 3D printing this *amazing* model, something with crazy overhangs and super cool internal structures. Then, BAM! The print fails because gravity is a harsh mistress. That’s where soluble supports strut into the spotlight. These nifty materials dissolve away in water (or other solvents), leaving your masterpiece untouched. Genius, right? They are like the unsung heroes of complex prints, letting you achieve geometries you wouldn’t think are possible. Here’s the thing, though, not all soluble supports are created equal, and that’s what we’re going to get into today.

The Usual Suspects: Common Soluble Support Materials

You’ve probably heard of some of the common players in the soluble support game. Polyvinyl Alcohol (PVA) is a classic — it’s water-soluble, relatively inexpensive, and works well with PLA. High Impact Polystyrene (HIPS), soluble in limonene, often partners with ABS. Each has its quirks. Think of PVA as reliable but a bit sensitive to moisture, like that one friend who cries during every movie. HIPS is tougher but needs special cleaning agents, almost like having a high-maintenance car.

High-Temperature Soluble Supports: When Things Get Hot

Here’s where things heat up – literally! For materials like Polycarbonate (PC) or Nylon, you need supports that can handle the same high temperatures. Regular PVA would simply melt and deform under such heat. You know, kind of like trying to bake a cake in a plastic container. These materials are engineered to withstand higher temperatures, which is required when you are printing those high performance polymers, giving you support without compromising the integrity of the final part.

The Secret Sauce: Advanced Material Formulations

This is where things get interesting. We’re not just talking about your run-of-the-mill PVA anymore. Material scientists have been busy tinkering, creating advanced formulations that offer improved thermal stability, better adhesion, and faster dissolution rates. Imagine a PVA that doesn’t clog your print nozzle and dissolves in minutes instead of hours. Sounds like magic? Well, it’s science–advanced polymer chemistry to be exact.

Printing Parameters: A Delicate Balancing Act

Soluble supports aren’t just “plug and play.” Getting them to work seamlessly requires tweaking your printing parameters. We’re talking temperature, print speed, layer height, and support density. You know that perfect cup of coffee you make? It’s the same idea – a delicate dance of variables. Get one wrong, and you’ll have a bad time. For example, printing your support interface layers too hot might cause them to fuse with the printed part.

Support Interface Layers: The Key to Clean Breakaways

Okay, let me explain something crucial: support interface layers. These are thin layers printed between the soluble support and the actual part. Think of them as a buffer zone. If you get these right, the support will come off cleanly, leaving a pristine surface. Mess them up, and you might as well be trying to pick a lock with a banana. The interface is typically a very thin layer (or two) that uses slightly different printing parameters to ensure easy and clean removal of the support structure.

Dissolution Techniques: Speeding Up the Process

So, you’ve successfully printed your model with soluble supports. Now comes the waiting game, right? Not necessarily! There are ways to accelerate the dissolution process. Agitation (think: a magnetic stirrer) helps circulate fresh solvent. Warmer temperatures speed things up too, but be careful not to overheat and warp your part. Honestly, it’s like doing laundry: a little agitation and warm water gets the job done faster!

Multi-Nozzle Printing: A Game Changer?

You know what? Some printers have multiple nozzles, which opens up a world of possibilities! You can dedicate one nozzle entirely to the build material and another to the soluble support. This eliminates material changes and streamlines the printing process. The only downside? It requires a printer with dual extrusion capabilities. It’s like having two chefs working on your meal simultaneously – faster and more efficient!

Software Solutions: Automating the Support Generation

Thankfully, you don’t need to manually design support structures. Modern slicing software can automatically generate them for you. Programs like Simplify3D and Cura have advanced algorithms that optimize support placement and density. You can even customize the support settings to perfectly match your materials and printing parameters. It’s like having a personal 3D printing assistant, making your life a whole lot easier.

Dealing with Difficult Geometries: Tips and Tricks

Even with all these advanced techniques, some geometries are just plain difficult. Deep cavities, intricate overhangs, and delicate features can still pose a challenge. In these cases, consider using a combination of support strategies. You could use a dense soluble support structure in critical areas and a sparser, easier-to-remove support elsewhere. It’s like choosing the right tool for the job!

Case Studies: Real-World Applications

Let’s get practical, okay? Soluble supports are used everywhere, from aerospace to medical devices. In aerospace, they enable the creation of complex ductwork and turbine blades. In medicine, they’re used to fabricate patient-specific surgical guides and anatomical models. Honestly, the applications are limitless. Soluble supports give product designers the ability to create more complex parts, without the compromises associated with traditional support removal.

The Future of Soluble Supports: What’s Next?

Where do we go from here? I imagine we’ll see even more advanced materials with tailored properties. Faster dissolution rates, higher temperature resistance, and improved adhesion are all on the horizon. Imagine self dissolving supports, or supports triggered by a unique energy source, like light. We might even see materials that can be recycled after dissolution, minimizing waste. The future is bright, my friends!

Common Pitfalls and How to Avoid Them

Alright, let’s talk about some common mistakes. Moisture contamination is a big one for water-soluble materials. Store your filaments in a dry environment, and use a filament dryer if necessary. Another pitfall is over-adhesion between the support and the part. This can lead to surface damage during removal. Make sure your interface settings are dialed in. Honestly, a little bit of prevention goes a long way!

Economical Uses of Soluble Support

Hey, money matters, right? Strategic use of soluble supports can actually save you money! By optimizing support structures in your slicing software, you can minimize the amount of material used. Plus, reducing failed prints saves both time and resources. In the long run, a sound soluble support strategy contributes to a more streamlined and cost-effective 3D printing workflow. Think of optimizing as a means of reducing waste by printing less material when you are prototyping a part.

Safety Considerations When Using Soluble Supports

Let’s not forget safety! Always wear appropriate personal protective equipment (PPE) when handling solvents. Work in a well-ventilated area to avoid inhaling fumes. And dispose of waste materials properly, following local regulations. You know, a little common sense goes a long way in keeping you safe and happy!

Conclusion: Embracing the Power of Dissolvable Supports

So, there you have it – a comprehensive look at advanced 3D printing techniques for soluble supports. By understanding the materials, mastering the printing parameters, and optimizing the dissolution process, you can unlock a new level of design freedom and create parts you never thought possible. So go ahead, give these tips a try! Happy printing, and may your supports dissolve with ease!

FAQ: Your Burning Questions Answered

Soluble supports are materials used during 3D printing that can be dissolved away after the print is complete, typically in water or another solvent. You use them to support complex geometries, overhangs, and internal structures that would otherwise be impossible to print without support.

Learn More About Soluble Supports

Read About Support Removal Strategies

Additional Resource on 3D Printing Support Structures

DISCLAIMER

Readers are advised to consult with professional engineers and material scientists before implementing any of the techniques described in this article. The information provided is intended for educational purposes only and should not be considered as a substitute for professional advice. The author and publisher disclaim any liability for any losses or damages arising from the use of this information.

Categories

- 3D Printer (517)

- Automatic Mugs (426)

- Cleaning Appliances (504)

- Electric Bikes (214)

- Electric Scooters (456)

- Electronic Gadgets (183)

Recent Comments

Archives

Product Gallery

-

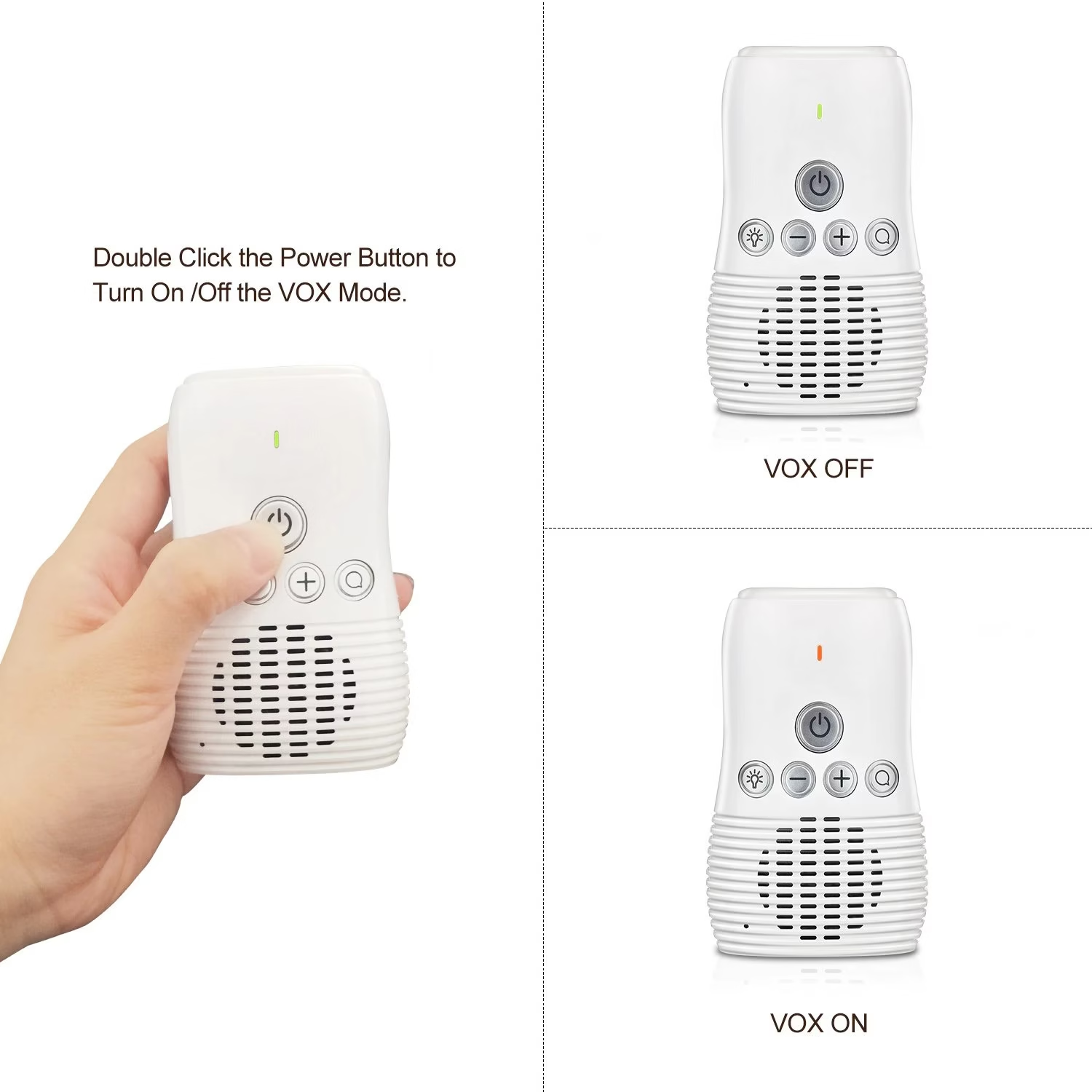

2.4Ghz Wireless Baby Monitor Small Portable Audio Baby Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 3.83 out of 5$25.24

2.4Ghz Wireless Baby Monitor Small Portable Audio Baby Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 3.83 out of 5$25.24 -

ABM01 2.4GHz Wireless Baby Monitor Audio Small Portable Babyphone Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 5.00 out of 5$31.30

ABM01 2.4GHz Wireless Baby Monitor Audio Small Portable Babyphone Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 5.00 out of 5$31.30 -

4.3 inch video baby monitor with 2 Cameras Pan Tilt Zoom,3000mAh Battery,Two-way Talk,Night Vision,Temperature,Feeding Reminder

$101.31 – $103.31Price range: $101.31 through $103.31

4.3 inch video baby monitor with 2 Cameras Pan Tilt Zoom,3000mAh Battery,Two-way Talk,Night Vision,Temperature,Feeding Reminder

$101.31 – $103.31Price range: $101.31 through $103.31

Robot Vacuums

Robot Vacuums Steam Cleaner

Steam Cleaner Window Robots

Window Robots

Self Stirring Mugs

Self Stirring Mugs Self Heating Mugs

Self Heating Mugs

Air Purifier

Air Purifier Dehumidifier

Dehumidifier Diffuser

Diffuser Humidifier

Humidifier

Panoramic Camera

Panoramic Camera Solar Camera

Solar Camera Window Door Sensor

Window Door Sensor Baby Monitor

Baby Monitor Small Cameras

Small Cameras

Electric Bike

Electric Bike Electric Bike Motor

Electric Bike Motor Electric Scooter

Electric Scooter Electric Skateboard

Electric Skateboard Hoverboard

Hoverboard

3D Printers

3D Printers 3D Printer Filament

3D Printer Filament