Simplify3D Walkthrough: 3D Printing Basics & Tutorials

So, you’re thinking about getting into 3D printing or maybe you’ve already dipped your toes in. That’s awesome! But let’s be real, it can feel like learning a whole new language, right? There’s a ton to wrap your head around – from understanding different filaments to figuring out the best software to use. Among the myriad of options, Simplify3D stands out as a powerful, versatile tool that can truly bring your 3D printing projects to life. But where do you start?

That’s where this guide comes in. I’m not just going to throw a bunch of technical jargon at you. Instead, we’re going to walk through the basics of 3D printing and how Simplify3D can be your best friend in this exciting adventure. Think of it as a friendly chat over coffee, where we break down complex topics into easy-to-understand concepts. Ready? Let’s jump in!

What Exactly IS Simplify3D, Anyway?

Okay, let’s get the introductions out of the way. Simplify3D is essentially a comprehensive software suite for 3D printing. It’s not just a slicer—though it does that job incredibly well. It’s more like a command center for your 3D printer. It takes your 3D models, slices them into layers, and generates the g-code that tells your printer exactly what to do. But it doesn’t stop there.

It also offers a wide range of advanced features, such as:

- Advanced Slicing: Fine-tune every aspect of your print.

- Print Simulation: See how your print will turn out *before* you start.

- Machine Control: Directly control and monitor your printer.

- Multi-Part Printing: Optimize printing multiple parts at once.

Sounds pretty cool, huh? But why should you even consider it when there are *so many* other options out there, some of them even free? Well, let me explain.

Why Choose Simplify3D Over Other Options?

Now, you might be thinking, “Hold on, there are tons of free slicers available. Why should I pay for Simplify3D?” That’s a totally valid question! Here’s the thing: while free options are great for getting started, Simplify3D offers a level of control, customization, and support that can save you a ton of time and frustration in the long run. Think of it like this: you *could* use a basic free photo editor, but if you’re serious about photography, you’d invest in something more powerful like Adobe Photoshop, right? Same principle here.

Here’s why Simplify3D often comes out on top:

- Superior Print Quality: The advanced slicing algorithms often result in better surface finish and stronger parts.

- Customization Galore: You can tweak just about every setting imaginable, giving you unparalleled control over your prints.

- Excellent Printer Compatibility: Simplify3D supports a vast range of 3D printers, and they’re constantly adding more.

- Top-Notch Support: Their support team is known for being responsive and helpful, which is a lifesaver when you’re troubleshooting tricky issues.

- Time Savings: The ability to optimize print settings and simulate prints beforehand can save you hours (and a lot of filament!)

Of course, it’s not all sunshine and rainbows. The price tag can be a barrier for some, and the sheer number of settings can be overwhelming at first. But for serious hobbyists and professionals, the investment is often well worth it.

Getting Started: Installing and Setting Up Simplify3D

Alright, you’ve decided to give Simplify3D a shot. Awesome! The first step is to get it installed and set up properly. Don’t worry, it’s not rocket science. Let’s walk through it step-by-step.

1. Downloading and Installing:

- Head over to the Simplify3D website and purchase a license.

- Once you’ve purchased it, you’ll receive a download link.

- Download the appropriate installer for your operating system (Windows, macOS, or Linux).

- Run the installer and follow the on-screen instructions.

2. Activating Your License:

- Launch Simplify3D.

- You’ll be prompted to enter your license key, which you received after purchasing.

- Enter your key and click “Activate.”

3. Configuring Your Printer:

This is where things get a little more specific. Simplify3D needs to know what kind of printer you have so it can generate the correct g-code.

- Go to “Help” > “Configuration Assistant.”

- A window will pop up with a list of pre-configured printer profiles.

- If your printer is on the list, select it and click “Add.”

But what if your printer isn’t on the list? No sweat! You can manually configure it. This requires a bit more technical knowledge, but I’ll give you the basic steps:

- Choose “Custom” from the list.

- You’ll need to enter details about your printer, such as:

- Build volume (the size of your print bed)

- Nozzle diameter

- Firmware type (e.g., Marlin, Repetier)

- This information is usually found in your printer’s manual or on the manufacturer’s website.

A Pro Tip: Many users share their printer profiles online. A quick search for “Simplify3D [Your Printer Model] profile” might save you a lot of time and effort!

Understanding the Simplify3D Interface: A Quick Tour

Okay, you’ve got Simplify3D installed and your printer configured. Now it’s time to familiarize yourself with the interface. Don’t worry, it’s not as intimidating as it looks. Think of it as learning the layout of a new kitchen – once you know where everything is, you’ll be whipping up masterpieces in no time!

Here’s a breakdown of the key areas:

- The Build Platform: This is the big, central area where you’ll see your 3D model. It represents the build area of your printer.

- The Process Settings Panel: Located on the left side, this is where you’ll find all the settings that control how your model is sliced and printed. This is where you’ll spend most of your time!

- The Toolbars: At the top, you’ll find toolbars with common actions like importing models, arranging parts, and generating g-code.

- The Machine Control Panel: If you connect your printer directly to Simplify3D, this panel lets you control it in real-time, adjust temperatures, and monitor progress.

- The Preview Mode: This is your best friend! It allows you to visualize how your model will be printed, layer by layer, before you even start the print.

Take some time to click around and explore each area. Hover your mouse over the icons to see tooltips explaining what they do. Don’t be afraid to experiment! The best way to learn is by doing.

Importing and Manipulating 3D Models

So, you know what Simplify3D is, you’ve got it all set up, and you’ve taken a quick tour of the interface. Now comes the fun part: bringing your 3D models into the software! This is where your creations start to come to life (virtually, at least).

Importing Models:

Simplify3D supports a variety of 3D file formats, including:

- .stl (the most common format)

- .obj

- .3mf

- .thing (for Thingiverse files)

To import a model, simply:

- Click “File” > “Import Models.”

- Select the file you want to import and click “Open.”

Your model will now appear on the build platform. Pretty easy, right?

Manipulating Models:

Once your model is imported, you can manipulate it in several ways:

- Moving: Click on the model and use the arrows to move it along the X, Y, and Z axes.

- Rotating: Use the rotation handles to rotate the model around each axis.

- Scaling: Use the scaling handles to change the size of the model. You can scale uniformly or independently along each axis.

- Arranging: Simplify3D has a handy “Arrange” feature that automatically positions your models on the build platform to optimize space.

Why is this important? Proper orientation and placement can significantly impact print quality, printing time, and the amount of support material needed. For example, minimizing overhangs can often lead to cleaner prints.

A Quick Tip: Make sure your model is sitting flat on the build platform. If it’s floating in the air, the printer won’t know where to start!

The Heart of 3D Printing: Understanding Process Settings

Okay, we’ve reached the core of Simplify3D – the process settings. This is where the magic happens, where you tell Simplify3D *exactly* how you want your model to be printed. Honestly, this is where a lot of people get intimidated, because there are *so many* settings to tweak. But don’t worry, we’ll break it down into manageable chunks.

A “process” in Simplify3D is essentially a set of instructions for printing a particular part of your model. You can have multiple processes in a single print job, allowing you to use different settings for different features (e.g., different layer heights for the base and the top).

Here are some of the most important settings you’ll encounter:

- Layer Height: This determines the thickness of each layer. Smaller layer heights result in smoother surfaces but increase printing time.

- Infill: This refers to the internal structure of your print. Higher infill percentages result in stronger parts but also use more filament.

- Print Speed: This controls how fast the printer moves. Faster speeds can reduce printing time but may also decrease print quality.

- Temperature: This sets the temperature of the nozzle and the build platform. Different filaments require different temperatures.

- Support Material: These are structures that support overhanging parts of your model. Simplify3D offers a lot of control over how support material is generated and placed.

- Retraction: This is the process of pulling the filament back into the nozzle when the printer moves between different sections of the print. Proper retraction settings can prevent stringing and blobs.

Where do you even start? A good approach is to start with the default settings for your printer and filament. Then, print a small test object and see how it turns out. From there, you can start tweaking individual settings to improve print quality or reduce printing time.

A Word of Caution: Changing too many settings at once can make it hard to diagnose problems. It’s best to make small, incremental changes and test the results.

Essential Materials: Choosing the Right Filament

You know what? Let’s talk filaments. Choosing the right filament is important, you know? It’s like picking the right paint for a masterpiece. You wouldn’t use watercolors on a car, would you? Same principle with 3D printing. So, what are your options?

- PLA (Polylactic Acid): This is the most popular filament. It’s biodegradable, easy to print, and great for beginners.

- ABS (Acrylonitrile Butadiene Styrene): Stronger and more heat-resistant than PLA, but can be trickier to print.

- PETG (Polyethylene Terephthalate Glycol): A good middle ground between PLA and ABS, offering good strength and ease of printing.

- TPU (Thermoplastic Polyurethane): A flexible filament, great for printing things like phone cases or flexible joints.

So, how do you choose?

Consider what you’re printing. Is it a decorative item? PLA might be perfect. A functional part that needs to withstand some stress? ABS or PETG could be better choices. Something that needs to bend or flex? TPU is your go-to.

Additionally, each filament has optimal temperature settings that you can configure in Simplify3D.

Generating G-Code and Printing Your Model

Alright, you’ve tweaked your process settings to perfection. Now it’s time to generate the g-code and finally print your model! This is where all your hard work pays off.

Generating G-Code:

- Click “Prepare to Print.” Simplify3D will start slicing your model based on the process settings you’ve defined.

- Once slicing is complete, you’ll see a preview of the g-code. You can use the slider to move through the layers.

- If everything looks good, click “Save Toolpaths to Disk.” Choose a location to save the g-code file.

Printing Your Model:

There are a few ways to get the g-code to your printer:

- SD Card: Copy the g-code file to an SD card and insert it into your printer. Then, select the file from your printer’s menu and start the print.

- USB Connection: Connect your printer to your computer via USB. In Simplify3D, go to “Machine Control Panel” and connect to your printer. Then, you can send the g-code directly to the printer.

- Wireless Connection: Some printers have built-in Wi-Fi. You can use Simplify3D to send g-code to these printers wirelessly.

Once the print starts, keep an eye on it for the first few layers to make sure everything is going smoothly. If you see any problems, you can stop the print and adjust your settings.

Troubleshooting Common 3D Printing Issues

Okay, let’s face it: 3D printing isn’t always smooth sailing. You’re going to run into problems sooner or later. Stringing, warping, layer adhesion issues—they’re all part of the game. But don’t get discouraged! Troubleshooting is a valuable skill that will make you a better 3D printer in the long run. These are some common issues:

- Stringing: Fine strands of filament between different parts of the print. This is usually caused by insufficient retraction.

- Warping: The corners of your print lifting off the build platform. This is often caused by poor bed adhesion or temperature issues.

- Layer Adhesion: Layers not sticking together properly. This can be caused by low temperatures, incorrect layer height, or poor calibration.

The key is experimentation. Change one setting at a time and see how it affects the print. And don’t be afraid to ask for help! The 3D printing community is generally very welcoming and helpful.

Advanced Techniques: Taking Your Prints to the Next Level

So, you’ve mastered the basics, and you’re churning out decent prints. Now what? It’s time to explore some advanced techniques that can take your prints to the next level. This is where Simplify3D really shines, offering a wealth of features to fine-tune your prints and achieve stunning results.

- Variable Layer Height: This allows you to use different layer heights for different parts of your model. For example, you can use a smaller layer height for the top surface to create a smoother finish, while using a larger layer height for the infill to save time.

- Multiple Processes: As mentioned earlier, you can use multiple processes in a single print job to apply different settings to different features. This is great for optimizing support material or using different infill patterns for different sections of your model.

- Custom Support Structures: Simplify3D allows you to create your own custom support structures, giving you unparalleled control over where support material is placed. This can be useful for supporting complex overhangs or minimizing the amount of support material needed.

By mastering these advanced techniques, you can unlock the full potential of Simplify3D and create truly exceptional 3D prints. Keep experimenting, keep learning, and keep pushing the boundaries of what’s possible!

Simplify3D Resources: Where to Find Help and Inspiration

You know, learning a new skill can be tough, but the good news is you’re not alone! There are tons of resources. Here are some great places to find help and inspiration:

- Simplify3D’s Website: Simplify3D.com – They have a wealth of tutorials, FAQs, and documentation.

- Online Forums: Sites like Reddit and the official Simplify3D forums are great places to ask questions and get help from other users.

- YouTube: There are tons of 3D printing channels on YouTube with tutorials, reviews, and tips.

- Thingiverse: A treasure trove of 3D models. You can download models for free and also see how other people have printed them.

Remember, every expert was once a beginner. Don’t be afraid to ask questions, experiment, and learn from your mistakes. The 3D printing community is here to support you on your journey!

Conclusion: Embracing the World of 3D Printing

Well, there you have it! A comprehensive walkthrough of Simplify3D and the basics of 3D printing. I know it can seem like a lot to take in at first, but don’t get overwhelmed. Just take it one step at a time, and remember to have fun along the way!

3D printing is an incredibly rewarding hobby and a powerful technology. It allows you to bring your ideas to life, create custom tools and parts, and even start your own business. By mastering Simplify3D, you’ll unlock a whole new level of creativity and control over your 3D printing projects.

So go forth, experiment, and create something amazing! The world of 3D printing is waiting for you.

Frequently Asked Questions

Disclaimer

This guide is intended for informational purposes only. 3D printing involves potential risks, including but not limited to burns, mechanical injuries, and exposure to fumes. Always use appropriate safety precautions and follow manufacturer’s instructions for your 3D printer and materials. The author and publisher are not responsible for any damages or injuries resulting from the use of this information. 3D printing can produce items that have various uses. It is the responsibility of the user to ensure compliance with all applicable laws and regulations regarding the creation, possession, and use of any printed object.

Categories

- 3D Printer (517)

- Automatic Mugs (426)

- Cleaning Appliances (504)

- Electric Bikes (214)

- Electric Scooters (456)

- Electronic Gadgets (183)

Recent Comments

Archives

Product Gallery

-

Wireless Video Baby Monitor with 2 Pcs Cam 4.3 Inch Display IR Night Vision Two Way Intercom Temperature Monitoring Babysitter

Rated 1.00 out of 5$114.00

Wireless Video Baby Monitor with 2 Pcs Cam 4.3 Inch Display IR Night Vision Two Way Intercom Temperature Monitoring Babysitter

Rated 1.00 out of 5$114.00 -

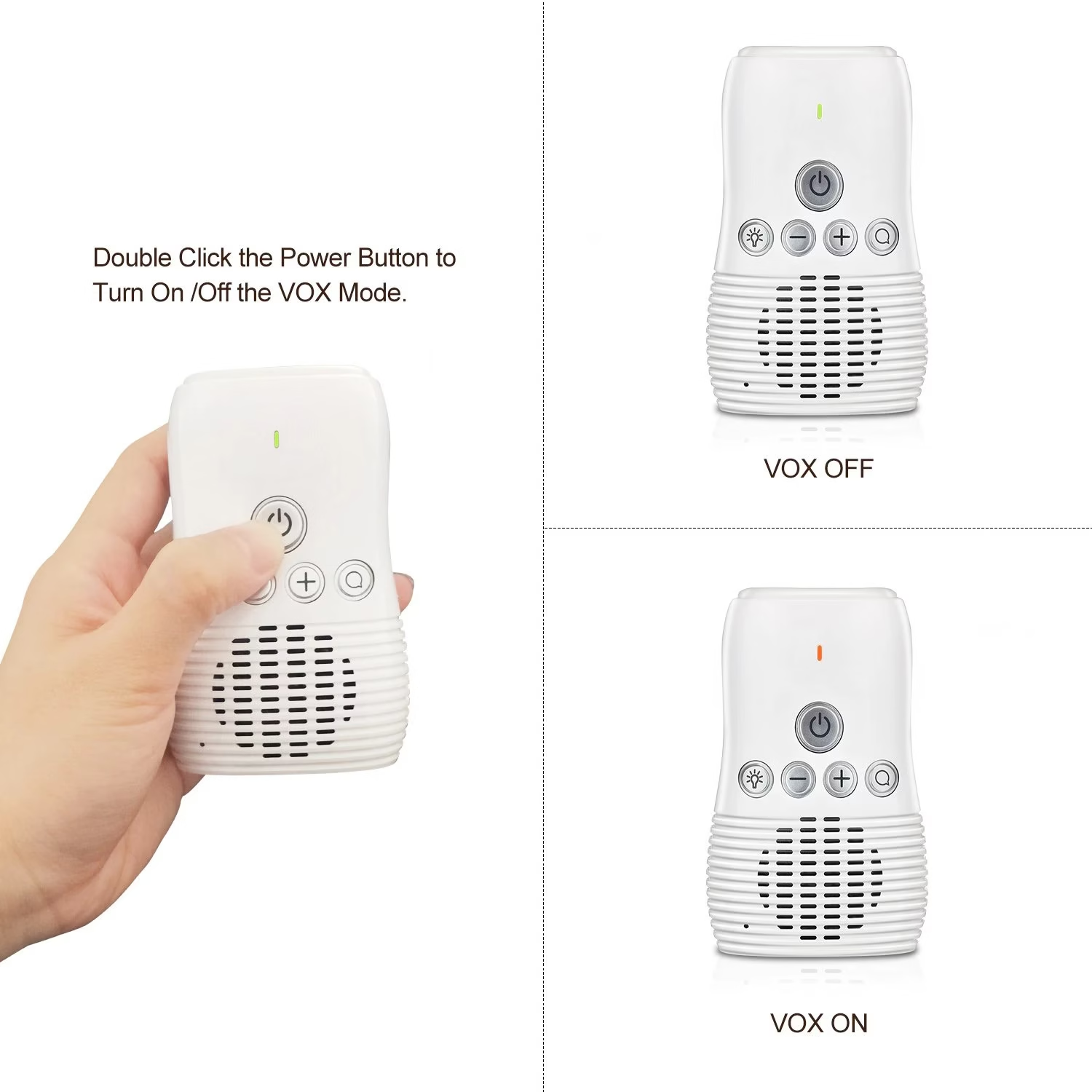

2.4Ghz Wireless Baby Monitor Small Portable Audio Baby Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 3.83 out of 5$36.00

2.4Ghz Wireless Baby Monitor Small Portable Audio Baby Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 3.83 out of 5$36.00 -

ABM01 2.4GHz Wireless Baby Monitor Audio Small Portable Babyphone Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 5.00 out of 5$44.00

ABM01 2.4GHz Wireless Baby Monitor Audio Small Portable Babyphone Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 5.00 out of 5$44.00

Robot Vacuums

Robot Vacuums Steam Cleaner

Steam Cleaner Window Robots

Window Robots

Self Stirring Mugs

Self Stirring Mugs Self Heating Mugs

Self Heating Mugs

Air Purifier

Air Purifier Dehumidifier

Dehumidifier Diffuser

Diffuser Humidifier

Humidifier

Panoramic Camera

Panoramic Camera Solar Camera

Solar Camera Window Door Sensor

Window Door Sensor Baby Monitor

Baby Monitor Small Cameras

Small Cameras

Electric Bike

Electric Bike Electric Bike Motor

Electric Bike Motor Electric Scooter

Electric Scooter Electric Skateboard

Electric Skateboard Hoverboard

Hoverboard

3D Printers

3D Printers 3D Printer Filament

3D Printer Filament