Multi-Material 3D Printing Basics & Tutorials

Ever looked at a 3D printed object and thought, “Man, I wish that part was flexible,” or “If only this section could conduct electricity”? Well, multi-material 3D printing is here to answer those wishes! It’s where 3D printing really starts to get interesting, opening doors to functional prototypes, complex designs, and products we couldn’t even dream of a few years ago.

What Exactly IS Multi-Material 3D Printing?

Let me explain: instead of just using one type of plastic, resin, or metal powder, multi-material 3D printing allows you to combine different materials within the same print job. Think of it like baking a cake with different layers – chocolate, vanilla, strawberry – all in one go. But instead of delicious cake, you get objects with varying properties, like hardness, flexibility, color, and more. We’re talking about printing hinges directly into a model, combining rigid parts with rubbery grips, or embedding conductive traces for simple electronics. Pretty nifty, right?

Why Bother with Multiple Materials Anyway?

Now, you might be thinking, “Okay, that sounds cool, but why would I even need it?” Fair question! Here’s the thing: multi-material printing solves a whole host of problems and opens up a world of possibilities:

- Functional Prototypes: Imagine designing a remote control and 3D printing the housing, buttons, and even flexible contacts all in one piece. You shave off weeks of production time!

- Complex Geometries: Support materials that dissolve away after printing? Yep, that’s multi-material magic, allowing you to create otherwise impossible shapes.

- Enhanced Aesthetics: Gradients, textures, and vibrant color combinations. Multi-material gives an aesthetic appeal that single-material prints just can’t match. Think personalized art pieces or eye-catching product packaging.

- Embedded Functionality: Conductive inks, sensors, or even bio-materials. The possibilities are truly endless when you start thinking about integrating functionality directly into the printed object.

- Reduced Assembly: Fewer parts to assemble means less labor, lower costs, and a faster time to market. It streamlines the entire production process.

A Quick Tech Rundown: How Does It Actually Work?

Okay, so how does this wizardry actually happen? Well, it depends on the 3D printing technology we’re talking about. Here’s a quick look at some of the most common methods:

Fused Deposition Modeling (FDM) – The Workhorse Approach

FDM is like the bread and butter of 3D printing. You use a nozzle to heat and extrude a plastic filament, layer by layer, to build your object. For multi-material printing, you need a printer with multiple extruders – basically, multiple nozzles feeding different materials. The printer switches between these extruders during the printing process, precisely placing each material where it’s needed.

PolyJet – Think Inkjet, But With Polymers

PolyJet is a different beast altogether. It uses print heads (similar to an inkjet printer) to jet tiny droplets of liquid photopolymers onto the build platform. Each layer is then cured with UV light. Multi-material PolyJet printers have multiple print heads, each dispensing a different material. This allows for incredibly fine detail and a wide range of material properties, including flexible and rigid materials.

Material Jetting – Precision Placement

You know what? Material Jetting is actually quite similar to PolyJet. These methods are technically the same. Just like polyjet printing, material jetting involves using print heads to deposit tiny droplets of various materials (photopolymers, waxes, etc.) onto a build platform. The key advantage here is the ability to create smooth surfaces and highly accurate parts with a very wide range of material properties.

Selective Laser Sintering (SLS) – Powder Power!

SLS uses a laser to fuse together powdered materials, layer by layer. Multi-material SLS is less common than other methods but can be achieved by layering different powders or using specialized powder blends. This technology is often used with polymers but can also work with metals, making it suitable for functional parts. SLS is especially useful for high-strength and complex geometries.

Binder Jetting – Glue and Powder Unite

Imagine spraying glue onto a powder bed, and that “glue” binds particles together. No? Well, let me explain. Binder jetting works similarly with the use of two materials: a powder-basedbuild material and a liquid binding agent. Using a print head, the binder is deposited in layers to create your desired object. The process is repeated until the part is finished leaving you with a solid part which gives room for multimaterial options.

Choosing Your Materials: What Are Your Options?

Alright, so you know how the printing works, but what can you actually print *with*? The material choices are constantly expanding, but here are some of the heavy hitters:

- PLA: Polylactic Acid is a Biodegradable Thermoplastic derived from renewable resources, such as corn starch or sugarcane . It’s relatively easy to print with, making it a popular choice for beginners.

- ABS: Acrylonitrile Butadiene Styrene is an oil-based thermoplastic with excellent strength and heat resistance. It’s commonly used for functional parts.

- TPU: Thermoplastic Polyurethane is a Flexible and elastic material with good abrasion resistance. It’s perfect for printing gaskets, seals, or anything that needs to bend.

- Nylon: Has a High strength, durability, and chemical resistance. It’s used for gears, hinges, and other demanding applications.

- PC: Polycarbonate, is known for its high impact resistance and transparency. This will make it ideal for lenses, safety glasses, and protective housings.

- Conductive Filaments: Plastics embedded with conductive particles, allowing you to print circuits and sensors.

- Support Materials: Materials designed to be easily removed or dissolved after printing, crucial for complex geometries.

Design Considerations: Think Before You Print

Multi-material printing isn’t just about loading up different filaments and hitting “print.” You need to consider a few design factors to get the best results:

Material Compatibility: Will They Play Nice Together?

Not all materials bond well. You need to make sure the materials you choose have good adhesion properties. Some materials might require special adhesives or surface treatments to stick together properly. It’s advisable to research material compatibility before printing to avoid delamination between layers.

Differential Shrinkage: Avoiding Warping Woes

Different materials shrink at different rates as they cool. This can lead to warping or internal stresses in your print. What can you do? Try to use materials with similar thermal expansion coefficients. If that’s not possible, consider adding features like fillets or ribs to reinforce the part.

Interface Design: How Do They Connect?

Think about how the different materials will join. A simple butt joint might not be strong enough. Consider using interlocking features, dovetails, or other designs that increase the surface area and mechanical strength of the joint. You know, the devil’s in the details!

Support Structures: Where to Place Them?

With multi-material prints, you might need to use different support materials for different sections of your model. Carefully plan the placement of support structures to ensure they’re easy to remove and don’t interfere with the functionality of the print. It may also be a good idea to use soluble supports like PVA which can be easily washed away.

Slicing Software: The Brain of Your 3D Printer

Slicing software takes your 3D model and turns it into instructions that your printer can understand. For multi-material printing, you need software that can handle multiple materials and assign them to different parts of the model. Here are a few popular choices:

- Simplify3D: A powerful paid slicer with advanced features for multi-material printing. It allows you to control every aspect of the printing process.

- Cura: A free and open-source slicer that’s constantly improving. It has decent multi-material support, though more advanced features might require some tweaking.

- PrusaSlicer: Another excellent free option, based on Slic3r. It offers good multi-material capabilities and is particularly well-suited for Prusa printers.

Tutorials: Getting Your Hands Dirty

Alright, let’s get practical! Here are some basic steps and considerations for your first multi-material print:

Setting Up Your Model: Assigning Materials

In your slicing software, you’ll need to import your 3D model and assign different materials to different parts. This usually involves selecting the relevant parts and choosing the desired material from a dropdown menu. Make sure your model is designed to be easily separated into different material zones. This can be done using CAD software like SOLIDWORKS or Fusion 360. Learn More

Configuring Your Slicer: Extruder Assignments and Settings

Each extruder on your printer will need to be configured with the correct material settings, such as temperature, flow rate, and retraction speed. You’ll also need to tell the slicer which extruder to use for each material. Proper calibration is also essential. This ensures accuracy and avoids issues such as material bleeding or weak layer adhesion.

Printing and Post-Processing: Patience is Key

Start your print and keep a close eye on the first few layers to make sure everything is going smoothly. Multi-material prints can be more prone to errors, so it’s important to catch problems early. After printing, you might need to remove support structures or do some light sanding or finishing to get your desired result. Depending on the support material used, dissolving it in water or a chemical solution may be necessary.

Troubleshooting: When Things Go Wrong

3D printing can be tricky, and multi-material printing adds another layer of complexity. Don’t worry, though! Here are a few common problems and how to fix them:

- Delamination: Layers separating? Increase the printing temperature, reduce printing speed, or try a different material combination.

- Clogging: Nozzle getting blocked? Clean or replace the nozzle, and ensure the filament is dry.

- Stringing: Excessive strings between parts? Adjust retraction settings in your slicer.

- Warping: Print lifting from the bed? Use a heated bed, apply adhesive, or try a different bed material.

The Future of Multi-Material 3D Printing: What’s Next?

The future of multi-material 3D printing is looking bright! We can expect to see even more advanced materials, faster printing speeds, and more sophisticated design tools. Imagine 3D printing entire electronic devices, customized medical implants, or even self-healing structures. Multi-material printing definitely has the potential to revolutionize industries, from manufacturing to healthcare to art and design. As technology develops companies are even working towards printers that can combine 5, 6, 8 or more materials.

In Conclusion: Are You Ready to Dive In?

Multi-material 3D printing might seem daunting at first, but it’s an incredibly rewarding technology. With a little bit of knowledge and some experimentation, you can unlock a whole new world of possibilities and create things you never thought possible. So go ahead, embrace the challenge, and start printing!

FAQ: Your Burning Questions Answered

- What is the biggest advantage of multi-material 3D printing?

-

The biggest advantage is the ability to create objects with varied properties in one print job, such as combining rigid components with flexible ones, reducing assembly time, and enabling complex designs.

- What types of materials can be used in multi-material 3D printing?

-

A wide range of materials can be used, including PLA, ABS, TPU, nylon, PC, conductive filaments, and support materials, each offering different properties like flexibility, strength, or conductivity.

- Is multi-material 3D printing more expensive than single-material printing?

-

Yes, multi-material 3D printing typically involves higher costs due to the need for specialized equipment (printers with multiple extruders or print heads) and potentially more expensive materials.

- What design considerations are important for multi-material prints?

-

Key design considerations include material compatibility, differential shrinkage, interface design (how materials connect), and the strategic placement of support structures to ensure successful printing and functionality.

- What slicing software is recommended for multi-material 3D printing?

-

Popular slicing software options include Simplify3D (paid), Cura (free and open-source), and PrusaSlicer (free), all of which offer features to manage multiple materials and assign them to different parts of the model.

- What are some common problems encountered during multi-material 3D printing?

-

Common issues include delamination (layer separation), nozzle clogging, stringing (excessive strings between parts), and warping (print lifting from the bed); each can be addressed with specific adjustments to printing parameters or material choices.

- Can I use any 3D printer for multi-material printing?

-

No, you need a 3D printer specifically designed for multi-material printing, which typically has multiple extruders or print heads to handle different materials simultaneously.

DISCLAIMER

3D printing can involve certain risks. Always follow the manufacturer’s guidelines for your printer and materials. Ensure proper ventilation and wear appropriate safety gear when handling chemicals or post-processing prints. If you’re new to 3D printing, consider starting with simpler projects before attempting multi-material prints. When in doubt, consult with experienced users or professionals.

Categories

- 3D Printer (517)

- Automatic Mugs (426)

- Cleaning Appliances (504)

- Electric Bikes (214)

- Electric Scooters (456)

- Electronic Gadgets (183)

Archives

About Team Ibuyem

View all posts by Team IbuyemProduct Gallery

-

Meian Smart Home Doorbell Wireless Security Doorbell IP65 Waterproof Outdoor Door Bell 60 Songs 5 Volume Adjustable Chime Kit

Rated 4.79 out of 5$13.00 – $29.00Price range: $13.00 through $29.00

-

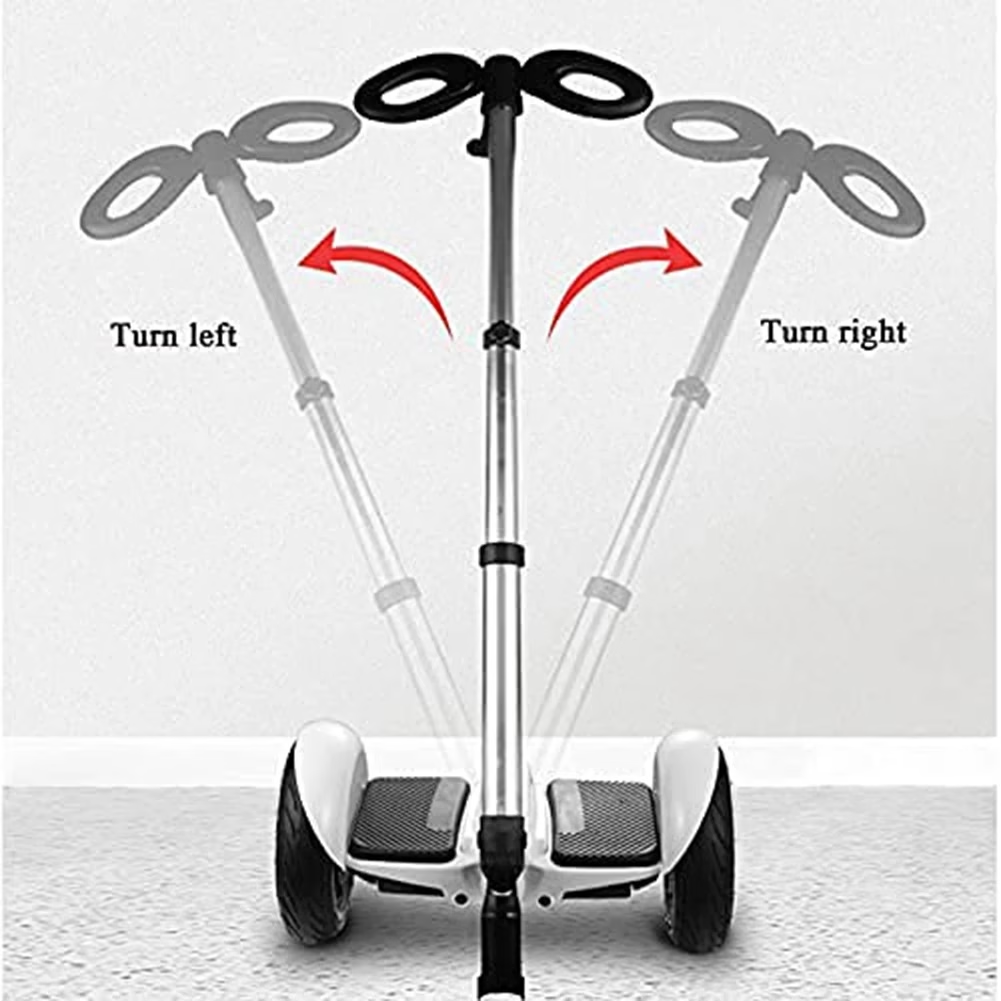

ABHS-Handlebar Suitable For Segway Ninebot Minipro Minilite Hoverboard Adjustable Three-In-One Function Pressure Handle

$59.00

ABHS-Handlebar Suitable For Segway Ninebot Minipro Minilite Hoverboard Adjustable Three-In-One Function Pressure Handle

$59.00

-

Modern Fashion 2 Wheel Smart Aluminum Hooverboard Self Balancing Scooter Kids Adults Electric Balance Scoter

$321.00

Modern Fashion 2 Wheel Smart Aluminum Hooverboard Self Balancing Scooter Kids Adults Electric Balance Scoter

$321.00

Robot Vacuums

Robot Vacuums Steam Cleaner

Steam Cleaner Window Robots

Window Robots

Self Stirring Mugs

Self Stirring Mugs Self Heating Mugs

Self Heating Mugs

Air Purifier

Air Purifier Dehumidifier

Dehumidifier Diffuser

Diffuser Humidifier

Humidifier

Panoramic Camera

Panoramic Camera Solar Camera

Solar Camera Window Door Sensor

Window Door Sensor Baby Monitor

Baby Monitor Small Cameras

Small Cameras

Electric Bike

Electric Bike Electric Bike Motor

Electric Bike Motor Electric Scooter

Electric Scooter Electric Skateboard

Electric Skateboard Hoverboard

Hoverboard

3D Printers

3D Printers 3D Printer Filament

3D Printer Filament

Recent Comments