Learning About Different Nozzle Sizes: 3D Printing Basics & Tutorials

So, you’re getting into 3D printing, huh? That’s awesome! It’s like having a mini-factory right on your desk. But before you start churning out figurines and functional parts, there’s a key component you need to get familiar with: the nozzle. It might seem like a small piece of metal, but trust me, it’s a game-changer. Let’s break down everything you need to know about nozzle sizes and how they impact your prints.

Why Nozzle Size Matters: More Than Just a Hole

Okay, let’s get real for a second. The nozzle isn’t just a hole. It’s the final gateway through which your melted filament flows onto the build plate. The size of this opening dictates a whole bunch of things, from print speed to layer resolution, and even the structural integrity of your finished product. It’s kind of like choosing the right paintbrush for a painting – a fine brush for detailed work and a broad brush for filling in large areas, you know?

Common Nozzle Sizes: A Quick Rundown

Alright, so what are the usual suspects? The most common nozzle size you’ll encounter is 0.4mm. It’s the all-rounder, the jack-of-all-trades, good for most general printing needs. But there’s a whole world beyond that!

- 0.25mm: For incredibly fine details. Think miniature models and intricate designs.

- 0.4mm: The standard. A balanced choice for speed and detail.

- 0.6mm: A step up in speed and strength, sacrificing a bit of fine detail.

- 0.8mm and larger: For rapid prototyping and large, sturdy parts where aesthetics aren’t the primary concern.

Honestly, it’s a spectrum. There’s no single “best” size, just the right one for a specific job. Don’t be afraid to experiment!

The Impact on Print Speed: Faster or Finer?

Here’s the thing: larger nozzles let you extrude more plastic in the same amount of time. More plastic means fewer passes to fill an area. Which basically means you can print faster. Think of it like using a wider pen to fill in a coloring book – it just gets done quicker, right?

But, and this is a big but, you lose some detail. A larger nozzle means thicker layers and less precision. It’s a trade-off. So, if you’re printing something that needs to look super smooth and detailed, stick with a smaller nozzle, even if it means waiting a bit longer. Want functional parts like brackets for shelving? A bigger nozzle will do the job faster – and it’ll be stronger too. You see, your project requirements determine your best choice here.

Detail and Resolution: Getting Down to the Nitty-Gritty

This is where nozzle sizes really shine (or, well, don’t shine, if you pick the wrong one). A smaller nozzle allows for finer layers, which translates to higher resolution. We’re talking about those tiny, almost invisible steps between layers that can make or break a detailed print.

Imagine printing a miniature figurine. With a large nozzle, you might lose some of the finer details – the subtle curve of a cheek, the intricate pattern on clothing. A smaller nozzle captures these nuances, resulting in a more accurate and visually appealing print. Of course, this accuracy comes at the cost of longer print times – a trade-off you need to consider. The level of detail you need depends on what you are printing, so choose wisely.

Strength and Durability: Building Solid Parts

So, what if detail isn’t your main concern? What if you just need a strong, reliable part that can withstand some stress? That’s where larger nozzles come into play. Remember when we talked about thicker layers? Those thicker layers aren’t just faster to print; they’re also stronger.

A part printed with a larger nozzle has better layer adhesion, meaning the layers are more tightly bound together. This makes the part more resistant to splitting or breaking under stress. Think of it like building a brick wall – thicker bricks provide a more solid structure, right? So, for functional prints or parts that need to withstand some wear and tear, a larger nozzle is often the way to go.

Material Compatibility: Not All Filaments Are Created Equal

Now, let’s talk materials. Different filaments have different properties, including viscosity (how easily they flow when melted). Some filaments, like flexibles (TPU or TPE) can be tricky to print with small nozzles because they require more pressure and can sometimes clog. Larger nozzles are generally more forgiving with these materials. You know, it’s kind of like trying to squeeze toothpaste through a tiny straw versus a wider one. Definitely less frustrating with the bigger straw!

On the flip side, some specialized filaments containing wood or metal particles can also be problematic with smaller nozzles due to the risk of clogging. Always check the filament manufacturer’s recommendations for the ideal nozzle size. It’ll save you a lot of headaches down the road.

Did you know that some filaments are even designed to change color based on temperature? Imagine the possibilities!

Calibrating for Success: Fine-Tuning Your Settings

Alright, you’ve chosen your nozzle size. Now what? Well, you can’t just slap it on and expect perfect prints. You need to calibrate your printer settings to match the new nozzle. This includes things like:

- Layer height: A good rule of thumb is to keep your layer height between 25% and 80% of your nozzle diameter. So, for a 0.4mm nozzle, your layer height should be somewhere between 0.1mm and 0.32mm.

- Flow rate: This controls how much filament your printer extrudes. You might need to adjust this to prevent over- or under-extrusion, which can lead to weak or messy prints.

- Print speed: Larger nozzles can usually handle higher print speeds, but you might need to slow things down for smaller nozzles to maintain detail.

Getting these settings dialed in can take some experimentation, but it’s worth the effort. Start with some test prints – simple shapes or calibration cubes – and adjust the settings until you’re happy with the results. There are tons of resources available online to help you, including calibration guides and forums where you can ask for advice from other 3D printing enthusiasts. Seriously, don’t be afraid to ask questions! The 3D printing community is generally really helpful.

Swapping Nozzles: A Practical Guide

Okay, so you’re ready to switch things up. Changing a nozzle is usually a pretty straightforward process, but it’s important to do it safely and correctly.

First of all, make sure your hot end is heated up! Trying to unscrew a cold nozzle is a recipe for disaster. Heat it up to around the printing temperature of your filament (usually around 200-220°C for PLA). Then, using a wrench, carefully unscrew the old nozzle. Be careful – it’s hot!

Next, screw in the new nozzle, tightening it snugly but not too tightly. You don’t want to strip the threads. Once it’s secure, let the hot end cool down before you start printing. Now go back to the Calibration section and repeat that process to make sure settings are tuned for the new nozzle.

Pro tip: Invest in a good set of wrenches specifically for nozzle changes. They’re not expensive, and they’ll make the job much easier and safer.

And please, for the love of all things 3D printed, don’t touch the hot end with your bare hands. Burns are no fun.

Beyond the Basics: Advanced Techniques

Alright, so you’ve mastered the fundamentals. What’s next? Well, the world of nozzle sizes opens up some pretty cool possibilities for advanced techniques. For instance, you can use different sized nozzles for different parts of the same print. Here’s where it gets tricky, but it can be worth it.

Imagine printing a figurine with a large, sturdy base and a highly detailed head. You could use a larger nozzle for the base to speed up printing and increase strength, and then switch to a smaller nozzle for the head to capture all those fine details. This requires some advanced slicing software settings and a bit of experimentation, but the results can be stunning.

Another cool technique is using different nozzle sizes to create variable layer heights. This allows you to optimize both speed and detail in different areas of the print. It’s all about finding the right balance for your specific needs.

The sky’s the limit, really! With a little creativity and some experimentation, you can push the boundaries of what’s possible with 3D printing.

Also make sure to check out Prusa knowledge base for more advanced techniques. Prusa Nozzle Article

Real-World Examples: Seeing Nozzle Sizes in Action

Enough theory, let’s get practical! Let’s look at some real-world examples of how different nozzle sizes can be used to achieve specific results. Consider a maker who wants to create custom drone frames. They might start with a large nozzle (0.8mm or even larger) to quickly prototype the basic frame structure. This allows them to test the overall design and make adjustments without spending a ton of time printing.

Once they’re happy with the design, they might switch to a smaller nozzle (0.4mm or 0.6mm) to print the final frame with improved strength and aesthetics. Or if the maker wants to add a detailed logo or intricate design to the frame, they might even use a 0.25mm nozzle for that specific area. Similarly, hobbyists printing tabletop gaming miniatures often use 0.25mm nozzles to capture the tiny details that make those models so appealing. The choice really is yours, my friend!

Maintenance and Care: Keeping Your Nozzles Happy

Like any precision component, 3D printer nozzles require some maintenance to keep them performing their best. The most common issue is clogging, which can be caused by a variety of factors, including:

- Low-quality filament: Cheap filament can contain impurities that clog the nozzle.

- Incorrect temperature settings: Printing at too low a temperature can cause the filament to melt improperly and clog the nozzle.

- Dust and debris: Dust and debris can accumulate in the nozzle over time, leading to clogs.

To prevent clogs, always use high-quality filament, double-check your temperature settings, and keep your printer clean. If you do experience a clog, there are several ways to clear it. You can try using a thin needle or acupuncture needle to push the blockage through the nozzle. There are even specialized “cleaning filaments” that can be used to remove stubborn clogs.

Also, remember to properly store your filaments. Humidity can affect some filaments. Use an airtight container to store any filaments. And use silica-gel packets to deal with moisture. This will prevent clogs and jams when printing.

Troubleshooting Tips: When Things Go Wrong

Okay, so you’ve done everything right (or so you think), but your prints are still coming out wonky. What gives? Here are some common troubleshooting tips related to nozzle sizes:

- Under-extrusion: This can be caused by a clog, an incorrect flow rate, or a nozzle that’s too small for the filament you’re using. Make sure your nozzle is clean and that your settings are properly calibrated.

- Over-extrusion: This can be caused by an incorrect flow rate or a nozzle that’s too large for the filament you’re using. Again, double-check your settings.

- Poor layer adhesion: This can be caused by a nozzle that’s too far from the build plate or incorrect temperature settings. Adjust your Z-offset and temperature settings.

The bottom line is that 3D printing sometimes requires some experimentation and problem-solving. Don’t get discouraged if things don’t go perfectly at first. The important thing is to learn from your mistakes and keep experimenting. After all, that’s half the fun! And be sure to check out Matterhackers for troubleshooting guides! Matterhackers Troubleshooting

And you know what? A little help goes a long way. Look for videos online where people have overcome similar issues.

Frequently Asked Questions

function toggleAnswer(id) {

var answer = document.getElementById(id);

if (answer.style.display === “none”) {

answer.style.display = “block”;

} else {

answer.style.display = “none”;

}

}

DISCLAIMER

This article is intended for informational purposes only. 3D printing involves certain risks, including but not limited to burns from hot components and exposure to potentially harmful fumes. Always follow the manufacturer’s safety guidelines for your 3D printer and materials. Wear appropriate safety gear, such as gloves and eye protection, and ensure adequate ventilation when operating your printer. The author and publisher are not responsible for any injuries or damages resulting from the use of this information.

Categories

- 3D Printer (517)

- Automatic Mugs (426)

- Cleaning Appliances (504)

- Electric Bikes (214)

- Electric Scooters (456)

- Electronic Gadgets (183)

Archives

About Team Ibuyem

View all posts by Team IbuyemProduct Gallery

-

Meian Smart Home Doorbell Wireless Security Doorbell IP65 Waterproof Outdoor Door Bell 60 Songs 5 Volume Adjustable Chime Kit

Rated 4.79 out of 5$13.00 – $28.00Price range: $13.00 through $28.00

-

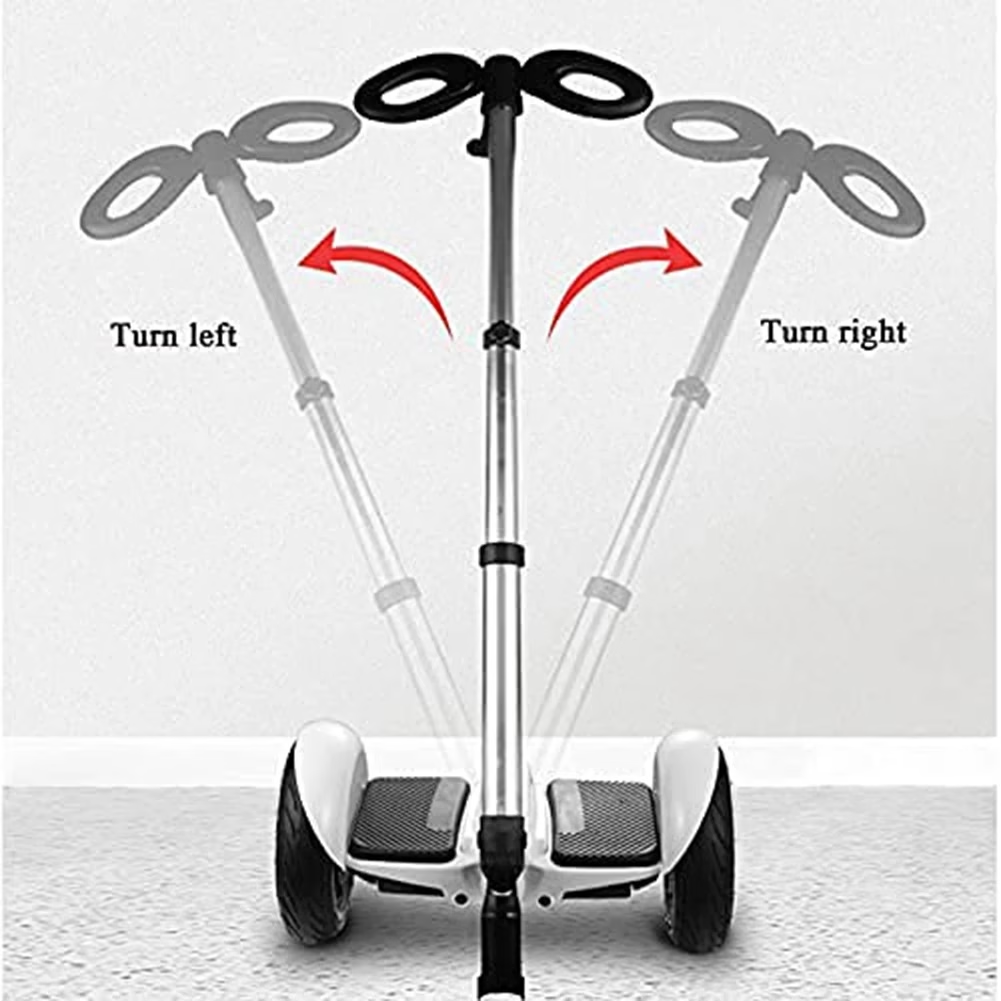

ABHS-Handlebar Suitable For Segway Ninebot Minipro Minilite Hoverboard Adjustable Three-In-One Function Pressure Handle

Rated 3.00 out of 5$60.00

ABHS-Handlebar Suitable For Segway Ninebot Minipro Minilite Hoverboard Adjustable Three-In-One Function Pressure Handle

Rated 3.00 out of 5$60.00 -

Modern Fashion 2 Wheel Smart Aluminum Hooverboard Self Balancing Scooter Kids Adults Electric Balance Scoter

$341.00

Modern Fashion 2 Wheel Smart Aluminum Hooverboard Self Balancing Scooter Kids Adults Electric Balance Scoter

$341.00

Robot Vacuums

Robot Vacuums Steam Cleaner

Steam Cleaner Window Robots

Window Robots

Self Stirring Mugs

Self Stirring Mugs Self Heating Mugs

Self Heating Mugs

Air Purifier

Air Purifier Dehumidifier

Dehumidifier Diffuser

Diffuser Humidifier

Humidifier

Panoramic Camera

Panoramic Camera Solar Camera

Solar Camera Window Door Sensor

Window Door Sensor Baby Monitor

Baby Monitor Small Cameras

Small Cameras

Electric Bike

Electric Bike Electric Bike Motor

Electric Bike Motor Electric Scooter

Electric Scooter Electric Skateboard

Electric Skateboard Hoverboard

Hoverboard

3D Printers

3D Printers 3D Printer Filament

3D Printer Filament

Recent Comments