How To Troubleshoot And Fix Retraction Settings

Alright, let’s talk retraction. If you’re deep into the world of 3D printing, you’ve probably already wrestled with this beast. If you’re new, trust me, you will. Retraction is that magical dance your 3D printer does to prevent stringing and oozing. It’s where the printer pulls the filament back a bit when it’s moving between printed parts. Sounds simple, right? Well, not always.

What is Retraction, Really?

So, what’s the deal with retraction? Basically, it’s about managing the molten plastic inside your printer’s hot end. When your printer needs to move from one spot to another without printing, it can sometimes leave a little trail of plastic – think of it like a spider web or fine hairs. Annoying, I know. Retraction is the technique that tells the printer to pull the filament back a little. This reduces the pressure and minimizes oozing. Think of it like releasing the gas pedal slightly on a car to prevent a sudden burst of speed when you don’t need it. It’s all about finesse, not brute force.

Why Does Retraction Matter So Much?

You know what? A perfect print can be ruined by the slightest bit of stringing. Retraction is what helps you achieve those clean, professional-looking models. Without proper retraction settings, you’re looking at:

- Stringing: Those annoying wisps of plastic between parts.

- Oozing: Blobs of plastic where they shouldn’t be.

- Poor Surface Finish: A generally messy-looking print.

It’s not just about aesthetics, though. These issues can also affect the structural integrity of your print. Imagine trying to assemble something with bits of plastic in the way. Not fun.

Identifying Common Retraction Problems

Let’s get down to the nitty-gritty. How do you know you have a retraction problem? The signs are usually pretty clear:

- Strings Like a Harp: If your print looks like it’s been attacked by a spider, that’s stringing.

- Blobs and Zits: Extra bits of plastic on the surface, especially at the start and end of movements.

- Rough Surface: Instead of a smooth finish, you get a bumpy ride.

These issues aren’t just annoying, they also impact the usability of your prints. Ever tried fitting parts together with blobs in the way? Yeah, not great.

Key Retraction Settings You Need to Know About

Alright, let’s talk numbers. The two main settings you’ll be tweaking are retraction distance and retraction speed. These are the bread and butter of your retraction strategy.

Retraction Distance

This is how much filament your printer pulls back. Too little, and you’ll still get stringing. Too much, and you might cause clogs or grinding of the filament. It’s a delicate balance. Typically, you’ll see recommendations ranging from 0.5mm to 7mm, but it varies WILDLY with different setups.

The material you are printing with also influences the retraction distance. For instance, flexible filaments like TPU often require shorter retraction distances, as excessive retraction can cause them to stretch and get stuck in the nozzle. Stiffer materials, such as ABS or PETG, may handle longer retraction distances better.

Retraction Speed

This is how fast the filament is pulled back. Too slow, and it won’t be effective. Too fast, and you risk grinding the filament or causing extruder issues. A good starting point is around 25mm/s, but again, experimentation is key.

It’s about the momentum, right? If your retraction speed is too slow, the molten filament can still ooze during travel moves. If it’s too fast, you can end up with the extruder slipping on the filament, especially with softer materials.

Step-by-Step Troubleshooting Guide for Retraction Settings

Okay, buckle up! Let’s get our hands dirty and start troubleshooting those retraction gremlins. Follow these steps, and you’ll be well on your way to cleaner prints. This is for the users that want to get past the constant stringing and move ot the next step.

Step 1: Start with a Retraction Test

Before you start changing settings willy-nilly, print a retraction test. You can find tons of these online. They’re designed to highlight stringing and oozing. Thingiverse is a great place to start! These tests usually consist of two or more tall, thin towers or shapes, spaced apart, forcing the printer to make travel moves and thus, show any stringing issues.

Evaluate the results:

- Minimal to no strings between the towers is the goal.

- If you see strands (strings), there is work to be done!

Step 2: Tweak Retraction Distance

Let’s start with the retraction distance. This is usually the first thing you want to adjust. The key is small incremental changes. Increase or decrease the distance by 0.5mm to 1mm at a time. Print after each adjustment and compare the results.

Adjusting retraction distance is like adjusting your car seat – a little bit goes a long way.

If you are still getting excessive stringing, you might want to consider increasing the retraction distance. However, go slowly because excessive retraction can cause other issues that are MORE annoying than stringing.

Step 3: Adjust Retraction Speed

If distance adjustments don’t fully solve the problem, let’s mess with the retraction speed. Again, small changes are the name of the game. Adjust the speed by 5mm/s increments. Too slow, and you’ll still get oozing. Too fast, and you might grind the filament.

Retraction speed is like the tempo of a song – too fast, and it’s chaotic, too slow, and it drags. 25 mm/s is the starting point. Increase it if needed.

Step 4: Temperature Towers

Nozzle temperature plays a huge role in how easily filament oozes. Before you get too far down the retraction rabbit hole, print a temperature tower.

If you are unfamiliar, a temperature tower is a test print designed to help you dial in the ideal printing temperature for a specific filament. It prints the same geometry multiple times, but changes the nozzle temperature for each layer.

Evaluate the results to determine which temperature minimizes stringing and maximizes surface quality. Make sure to also check the layer adhesion.

Step 5: Combing Mode Considerations

Combing mode tells your printer to keep the nozzle inside the printed part during travel moves, which can hide some stringing. You sacrifice a little print time, but it pays dividends depending on your models.

Combing mode is like taking the scenic route – it might take a bit longer, but the view (or in this case, the print quality) is worth it.

Enable combing mode to see what happens. You can even tell it where to comb, not just ON or OFF.

Step 6: Filament Quality

Sometimes, the issue isn’t your settings, it’s your filament! Low-quality filament can have inconsistent diameter or moisture, leading to poor retraction performance. Try a different spool from a reputable brand.

Filament is like the ingredients in a recipe – the better the quality, the better the final product. Consider a filament dryer if you want to keep using the older filament.

Step 7: Extruder Calibration

An improperly calibrated extruder might not be feeding the correct amount of filament, which can manifest as retraction problems. Calibrate your extruder to ensure it’s pushing the right amount of plastic.

Calibrating your extruder is like tuning a musical instrument – it ensures everything is in harmony. You may actually see a significant difference based on the results of this.

Step 8: Review and Adjust Nozzle Condition and Maintenance

A partially clogged nozzle can cause inconsistent extrusion, leading to stringing and oozing. Clean or replace your nozzle to ensure smooth filament flow.

Replace the nozzle as needed!

Step 9: Iterate

Unfortunately, not all 3-D printing is a one try kind of deal. You might tweak one thing, then have problems somewhere else. So, keep tweaking! It might take a while, but it will be worth it!

Iterating is like playing a video game – it might take a few tries to get it right, but it is satisfying when you do! Just keep trying, and keep tweaking.

Dealing with Specific Materials

Not all filaments are created equal. Different materials behave differently and require different retraction settings. Let’s look at a few common ones.

PLA (Polylactic Acid)

PLA is generally forgiving and doesn’t require extreme retraction settings. A good starting point is 1-3mm distance and 25-40mm/s speed.

PLA is like the vanilla ice cream of 3D printing – simple, reliable, and generally well-behaved.

ABS (Acrylonitrile Butadiene Styrene)

ABS tends to string more than PLA and might require slightly higher retraction distances, around 3-6mm, and similar speeds.

ABS is like that one friend who’s a bit more temperamental – it needs a bit more attention, but it’s worth it for the results.

PETG (Polyethylene Terephthalate Glycol)

PETG is known for being stringy. You might need to experiment with higher retraction distances and speeds. Try 3-7mm distance and 30-50mm/s speed.

PETG is like the wild child – it has its quirks, but it’s also incredibly versatile and strong.

TPU (Thermoplastic Polyurethane)

Flexible filaments like TPU are tricky. They often require very short retraction distances, sometimes even disabling retraction altogether. TPU distance settings vary wildly, and TPU is highly dependent on the type and setup of the printer.

TPU is like a slinky – flexible, fun, but easily tangled if you’re not careful.

Advanced Techniques for Tricky Prints

Sometimes, the simple tweaks just aren’t enough. For those challenging models, you might need to pull out the big guns.

Coasting

Coasting stops extruding filament right before the end of a movement, using the remaining pressure in the nozzle to complete the line. This can reduce oozing at the end of movements.

Coasting is like drafting in a race – it uses momentum to your advantage. To use coasting, find and enable it with reasonable settings.

Wipe

Wipe instructs the nozzle to move slightly over the already printed surface at the end of a movement, helping to clean off any excess plastic.

Wipe is like giving your nozzle a little spa treatment – it cleans things up and gets rid of any stragglers. To use it, find it in your setting and tweak it. You may want to change the distance settings.

Travel Speed

Increasing your travel speed can reduce stringing by minimizing the time the nozzle spends moving between parts. Just be careful not to go too fast, as it can affect print quality.

Travel speed is like teleportation – the faster you move, the less time you have to cause trouble. Just be cautious and test.

Preventive Measures: Keeping Retraction Issues at Bay

The best way to deal with retraction issues is to prevent them in the first place. Here are some tips to keep your printer running smoothly.

Regular Maintenance

Keep your printer clean and well-maintained. Clean the nozzle regularly, check for loose screws, and lubricate moving parts.

Regular maintenance is like going to the dentist – it’s not always fun, but it prevents bigger problems down the road.

Proper Filament Storage

Store your filament in a dry, airtight container to prevent moisture absorption. This is especially important for materials like nylon and PETG.

Proper filament storage is like keeping your snacks in a sealed container – it keeps them fresh and ready to go.

Software Updates

Keep your slicer software and printer firmware up to date. Updates often include improvements to retraction algorithms and other performance enhancements.

Software updates are like getting new gadgets – they often come with cool new features and bug fixes.

Conclusion: Taming the Retraction Beast and Creating Stunning Prints

And there you have it! A comprehensive guide to troubleshooting and fixing retraction settings! It’s a journey, not a destination. Experiment, iterate, and don’t be afraid to try new things. With a little patience and persistence, you’ll be printing stunning, string-free models in no time.

Remember, 3D printing is as much an art as it is a science. So, have fun, be creative, and happy printing!

Frequently Asked Questions about Retraction Settings

For PLA, a retraction distance of 1-3mm is generally a good starting point. However, this can vary based on your specific printer and setup. It’s always best to run a retraction test to dial in the perfect setting.

Retraction speed affects how quickly the filament is pulled back. If it’s too slow, oozing might still occur. If it’s too fast, it can cause the extruder to grind the filament. A good starting point is around 25-40mm/s, but experimentation is key.

Absolutely. Low-quality filament with inconsistent diameter or moisture can lead to poor retraction performance. Always use good-quality filament and dry it properly if needed.

Combing mode tells the printer to keep the nozzle inside the printed part during travel moves, which can hide stringing. It’s a useful technique for reducing visible stringing, though it might increase print time slightly.

It’s a good idea to calibrate your extruder whenever you notice inconsistent extrusion, especially after making changes to your printer or switching to a new type of filament. Regular calibration ensures accurate filament feeding.

Nozzle temperature affects how easily filament oozes. Printing at too high a temperature will make oozing more likely. Print a temperature tower to dial in the best settings.

PETG tends to be stringy because it remains molten at a lower temperature and can be prone to oozing. Higher retraction distances and speeds can mitigate this, along with careful temperature control.

DISCLAIMER

3D printing involves working with heated components and moving parts. Always follow safety guidelines and take necessary precautions to prevent injury. The information provided here is based on general 3D printing knowledge, and individual results may vary. Experiment with settings carefully and at your own risk. Consult with a professional if you’re unsure about any aspect of 3D printing safety or operation.

Categories

- 3D Printer (517)

- Automatic Mugs (426)

- Cleaning Appliances (504)

- Electric Bikes (214)

- Electric Scooters (456)

- Electronic Gadgets (183)

Archives

About Team Ibuyem

View all posts by Team IbuyemProduct Gallery

-

Meian Smart Home Doorbell Wireless Security Doorbell IP65 Waterproof Outdoor Door Bell 60 Songs 5 Volume Adjustable Chime Kit

Rated 4.79 out of 5$13.00 – $29.00Price range: $13.00 through $29.00

-

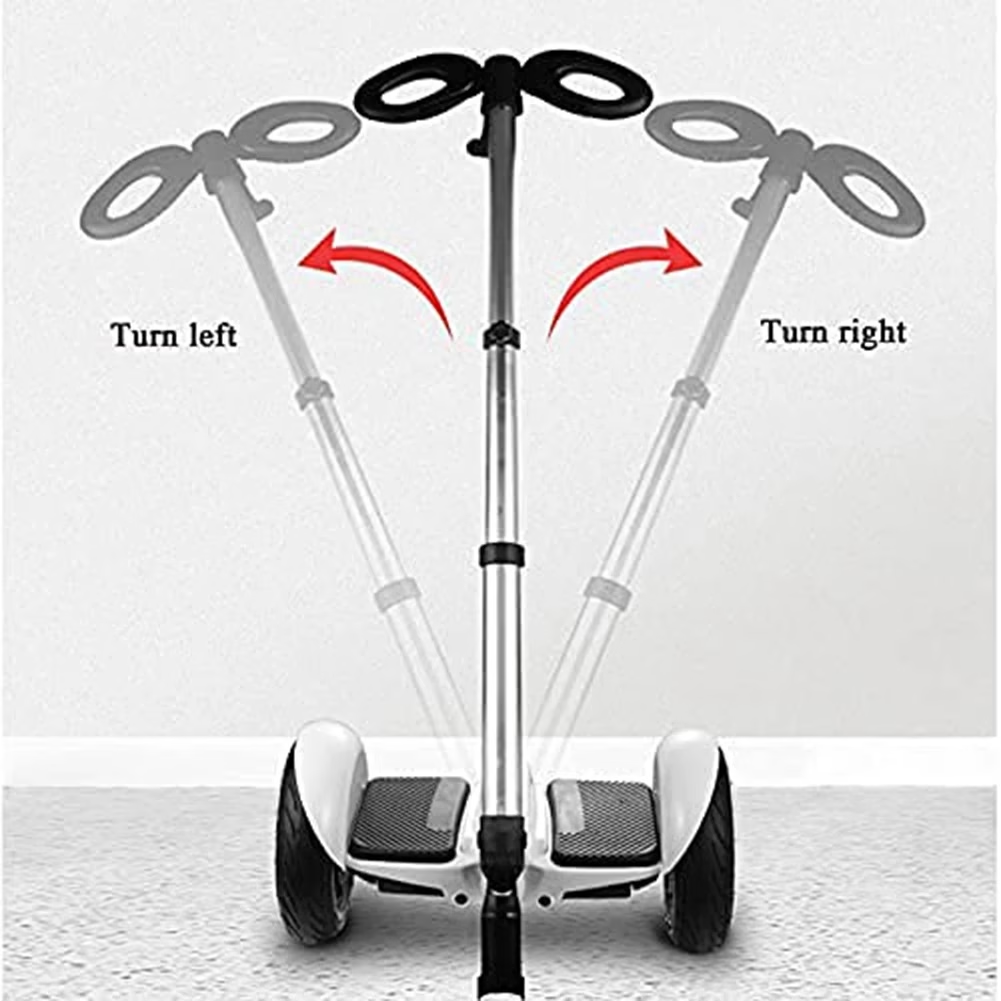

ABHS-Handlebar Suitable For Segway Ninebot Minipro Minilite Hoverboard Adjustable Three-In-One Function Pressure Handle

$59.00

ABHS-Handlebar Suitable For Segway Ninebot Minipro Minilite Hoverboard Adjustable Three-In-One Function Pressure Handle

$59.00

-

Modern Fashion 2 Wheel Smart Aluminum Hooverboard Self Balancing Scooter Kids Adults Electric Balance Scoter

$321.00

Modern Fashion 2 Wheel Smart Aluminum Hooverboard Self Balancing Scooter Kids Adults Electric Balance Scoter

$321.00

Robot Vacuums

Robot Vacuums Steam Cleaner

Steam Cleaner Window Robots

Window Robots

Self Stirring Mugs

Self Stirring Mugs Self Heating Mugs

Self Heating Mugs

Air Purifier

Air Purifier Dehumidifier

Dehumidifier Diffuser

Diffuser Humidifier

Humidifier

Panoramic Camera

Panoramic Camera Solar Camera

Solar Camera Window Door Sensor

Window Door Sensor Baby Monitor

Baby Monitor Small Cameras

Small Cameras

Electric Bike

Electric Bike Electric Bike Motor

Electric Bike Motor Electric Scooter

Electric Scooter Electric Skateboard

Electric Skateboard Hoverboard

Hoverboard

3D Printers

3D Printers 3D Printer Filament

3D Printer Filament

Recent Comments