You know, there’s something deeply satisfying about tackling a DIY project around the house. But what if I told you that 3D printing could take your craftsmanship to the next level? Yeah, I’m talking about custom jigs. They’re not just some fancy gadget; they’re game-changers for accuracy and efficiency. Let’s get into it!

What Exactly is a Jig, Anyway?

A jig is essentially a tool you use to make repetitive tasks easier and more precise. Think of it as a guide or a template. Instead of measuring and marking every single time, a jig lets you do the same thing over and over with consistent results. Carpenters have been using them for ages, but 3D printing? That’s a whole new ballgame.

Why Bother 3D Printing Jigs?

Here’s the thing: traditional jigs are fine, but they can be a pain to make, especially if you need something super specific. 3D printing lets you design and create custom jigs tailored exactly to your needs. So, why should you consider it?

- Customization: Need a jig for an odd angle or unique shape? No problem. Design it, print it, and you’re good to go.

- Cost-Effective: For one-off projects, printing a jig can be cheaper than buying a specialized tool.

- Rapid Prototyping: Quickly test and refine your jig design. Mess up? Tweak the design and print another one.

- Accessibility: Who wouldn’t want a specialized jig to help make their life easier?

Essential 3D Printing Materials

Alright, let’s talk materials. It’s not just about hitting “print.” The material you choose for your jigs can make a big difference in durability and performance. You know what I mean? Here are a few options to consider:

- PLA (Polylactic Acid): This is your go-to for general use. It’s easy to print, biodegradable, and works well for light-duty jigs.

- ABS (Acrylonitrile Butadiene Styrene): Stronger and more heat-resistant than PLA. Useful for jigs that might experience a bit of friction or heat.

- PETG (Polyethylene Terephthalate Glycol): A good middle ground between PLA and ABS. It’s durable, flexible, and has good chemical resistance.

- Nylon: For those really demanding tasks. Nylon is super strong and wear-resistant, perfect for jigs that need to withstand a lot of use.

Each material brings its own set of benefits. Think about the kind of stress your jig will endure and choose accordingly. Honestly, this choice alone can make or break its usefulness.

Designing Your Jig: Tips and Tricks

Okay, you’re convinced. Now, how do you actually design a jig? Don’t sweat it. Here’s what you need to keep in mind:

- CAD Software: Software is key.

- Fusion 360: (Free for hobbyists) A powerhouse with tons of features.

- Tinkercad: (Free and browser-based) Perfect for beginners.

- SolidWorks: Industry-standard, but pricier.

- Consider Tolerances: 3D printers aren’t perfect. So, what about a little extra wiggle room in your design for a snug fit?

- Ergonomics: Make sure the jig is comfortable to use, especially if you’re doing repetitive tasks. A good grip matters.

- Think About Support: How will the jig attach to your workpiece or tool? Clamps, screws, or even magnets can be your friend.

Practical DIY Projects That Benefit From 3D Printed Jigs

Alright, let’s get into some real-world examples. Where can these 3D-printed jigs actually make a difference?

- Woodworking:

- Drilling Jigs: Exactly spaced holes? A 3D-printed jig can achieve that.

- Cutting Guides: Achieve straight cuts on your woodworking projects.

- Sanding Blocks: Custom-shaped sanding blocks for those pesky curves.

- Metalworking:

- Welding Jigs: Hold pieces in place for precise welds.

- Bending Jigs: Makes it easy to create repeatable bends in sheet metal or wire.

- Home Improvement:

- Painting Templates: Stencil designs for unique wall patterns.

- Fixture Installation: Jigs for drilling holes perfectly aligned – think towel racks or shelves.

Tips for Successful 3D Printing of Jigs

So, you’ve got your design ready to go. Not so fast! Here’s how to make sure your print turns out great:

- Calibration: Ensure your 3D printer is properly calibrated. Trust me, it makes a difference. Bed adhesion, nozzle height – nail it all.

- Print Settings: Adjust settings like layer height and infill density. Higher infill for stronger jigs.

- Support Structures: Use support structures wisely, especially for complex shapes or overhangs.

- Post-Processing: Remove supports carefully and smooth any rough edges with sandpaper or a file.

These details can be easy to overlook, but they’re crucial for getting a durable and accurate jig. Pay attention, and you’ll save yourself a lot of headaches.

Designing for Specific Tools

Let’s talk specifics. The best jigs are designed with particular tools in mind. I mean, you wouldn’t use a wrench to hammer a nail, right? Here are a few examples to spark your creativity:

- Drill Press Jigs: Make drilling holes at perfect 90-degree angles a breeze.

- Router Jigs: Guide your router for creating clean grooves and edges.

- Saw Jigs: Ensures straight cuts every time.

Tailoring your jig to the tool will improve the effectiveness and safety, preventing slips and errors. Trust me, this is a level-up move.

Real-World Example: A Custom Dowel Drilling Jig

Let’s walk through a specific example—a dowel drilling jig. You know when you’re joining two pieces of wood together with dowels? Getting those holes aligned perfectly can be a real pain. With a custom 3D-printed jig, it’s a breeze.

- Design: Create a jig with holes that match the diameter and spacing of your dowels.

- Printing: Print the jig using a durable material like PETG.

- Usage: Clamp the jig onto the wood pieces and drill through the guide holes.

Imagine how much time and frustration this saves! No more misaligned dowels or wobbly joints. I’m not kidding; this is a game-changer for any woodworking enthusiast.

How to Improve Your 3D-Printed Jig Designs

Like anything, practice makes perfect. But here are some pro tips to accelerate your learning curve:

- Iterate: Don’t be afraid to experiment and refine your designs. Print a prototype, test it, and make adjustments.

- Community Feedback: Share your designs online and solicit feedback from other makers. Platforms like Thingiverse are goldmines.

- Learn From Others: Take inspiration from existing jig designs. What works well? What could be improved?

Beyond the Basics: Advanced Jig Concepts

If you’re feeling ambitious, consider these advanced concepts:

- Modular Jigs: Design jigs that can be adapted for multiple tasks.

- Adjustable Jigs: Allow for variable dimensions or angles.

- Multi-Material Jigs: Combine different materials for added strength or flexibility.

These techniques can make your jigs even more versatile and effective. It’s like unlocking new superpowers for your DIY projects!

Safety First: Precautions When Using 3D-Printed Jigs

Always remember, safety is paramount. Just because you 3D printed something, that doesn’t make it indestructible. Here are some guidelines:

- Material Limitations: Understand the limitations of your chosen material. Don’t overload a PLA jig.

- Proper Fastening: Ensure the jig is securely attached to your workpiece or tool.

- Eye Protection: Always wear safety glasses when working with power tools.

- Common Sense: If something feels unsafe, don’t do it. It’s better to be cautious than sorry.

Troubleshooting Common Issues

Sometimes, things don’t go as planned. Here are some common issues and how to fix them:

- Jig Breaks: Use a stronger material or reinforce the design.

- Poor Fit: Adjust your CAD design to account for printer tolerances.

- Slippage: Add non-slip surfaces or improve the clamping mechanism.

The Future of 3D Printing in Home Improvement

3D printing is only going to become more integrated into our homes and workshops. What else can we look forward to?

- Better Materials: Stronger, more durable filaments will open up new possibilities.

- More Affordable Printers: Lower costs will make 3D printing accessible to everyone.

- Smarter Designs: Advanced CAD software and online communities will foster innovation.

Honestly, the possibilities are limitless. Get in on the action now and start printing your way to DIY mastery!

Ready to Get Started?

So there you have it – a deep dive into the world of custom 3D-printed jigs. Whether you’re a woodworking enthusiast, a metalworking master, or just someone who loves tackling home improvement projects, 3D printing offers a wealth of possibilities. So what are you waiting for?

- Research 3D printers, such as the Prusa or the Creality

- Take CAD lessons through sites like Autodesk

Frequently Asked Questions (FAQ)

DISCLAIMER

Please be advised that 3D printing involves the use of machinery and materials that may pose risks if not handled properly. Always follow safety guidelines provided by the manufacturer of your 3D printer and materials. Ensure adequate ventilation when printing and wear appropriate protective gear, such as safety glasses, when handling tools and materials. The information provided in this article is for informational purposes only and should not be considered professional advice. The author and publisher are not responsible for any injury, loss, or damage arising from the use of this information.

Categories

- 3D Printer (517)

- Automatic Mugs (426)

- Cleaning Appliances (504)

- Electric Bikes (214)

- Electric Scooters (456)

- Electronic Gadgets (183)

Archives

About Team Ibuyem

View all posts by Team IbuyemProduct Gallery

-

Meian Smart Home Doorbell Wireless Security Doorbell IP65 Waterproof Outdoor Door Bell 60 Songs 5 Volume Adjustable Chime Kit

Rated 4.79 out of 5$8.97 – $20.28Price range: $8.97 through $20.28

-

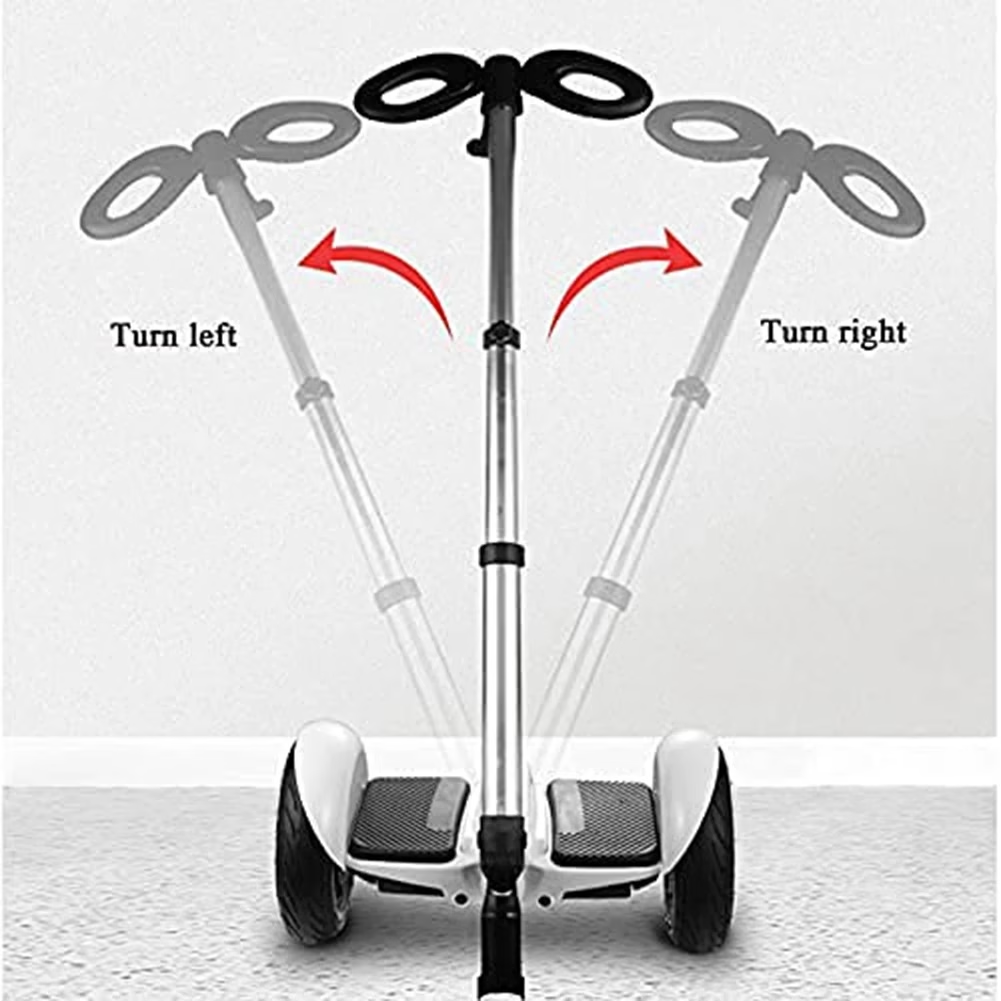

ABHS-Handlebar Suitable For Segway Ninebot Minipro Minilite Hoverboard Adjustable Three-In-One Function Pressure Handle

$41.90

ABHS-Handlebar Suitable For Segway Ninebot Minipro Minilite Hoverboard Adjustable Three-In-One Function Pressure Handle

$41.90

-

Modern Fashion 2 Wheel Smart Aluminum Hooverboard Self Balancing Scooter Kids Adults Electric Balance Scoter

$230.85

Modern Fashion 2 Wheel Smart Aluminum Hooverboard Self Balancing Scooter Kids Adults Electric Balance Scoter

$230.85

Robot Vacuums

Robot Vacuums Steam Cleaner

Steam Cleaner Window Robots

Window Robots

Self Stirring Mugs

Self Stirring Mugs Self Heating Mugs

Self Heating Mugs

Air Purifier

Air Purifier Dehumidifier

Dehumidifier Diffuser

Diffuser Humidifier

Humidifier

Panoramic Camera

Panoramic Camera Solar Camera

Solar Camera Window Door Sensor

Window Door Sensor Baby Monitor

Baby Monitor Small Cameras

Small Cameras

Electric Bike

Electric Bike Electric Bike Motor

Electric Bike Motor Electric Scooter

Electric Scooter Electric Skateboard

Electric Skateboard Hoverboard

Hoverboard

3D Printers

3D Printers 3D Printer Filament

3D Printer Filament

Recent Comments