So, you’re stepping into the awesome world of 3D printing? That’s fantastic! It’s a field that can be both incredibly rewarding and, let’s be honest, a little daunting at first. You’re probably wondering, “Where do I even begin?” Well, choosing the right material is your first big step. Think of it like choosing the right ingredients for a recipe – it can make or break the final dish. This guide will walk you through the best materials for beginners, so you can start your 3D printing adventure with confidence.

Understanding the Basics: What Makes a Material Beginner-Friendly?

When we talk about beginner-friendly materials, what are we really looking for? Well, several factors come into play. First, ease of printing is key. You want something that doesn’t require a PhD to get decent results. Then, there’s the material’s properties. Is it strong enough for your intended uses? Is it environmentally friendly? And of course, let’s not forget about cost. As a beginner, you probably don’t want to blow your entire budget on a single spool of filament, right?

PLA: The King of Beginner 3D Printing

PolyLactic Acid, or PLA as it’s commonly known, is pretty much the gold standard for beginner 3D printing. It’s derived from renewable resources like cornstarch or sugarcane, making it biodegradable under the right conditions. Plus, it’s super easy to work with. But ease of use isn’t the only thing, you know?

Why Beginners Love PLA:

- Low Printing Temperature: PLA prints at relatively low temperatures (around 180-220°C), which means less energy consumption.

- Minimal Warping: Warping is when the corners of your print lift off the build plate during printing. PLA is known for minimal warping, which is a huge plus.

- No Heated Bed Required: While a heated bed can improve adhesion, it’s often not necessary with PLA, saving you energy and complexity.

- Wide Availability and Colors: PLA comes in a rainbow of colors and is readily available from numerous suppliers. You can find it almost anywhere 3D printing supplies are sold.

- Low Odor: Unlike some other materials, PLA has a very mild, almost sweet smell when printing. Your workspace won’t stink!

Potential Downsides of PLA:

- Lower Heat Resistance: PLA starts to soften at around 60°C, so it’s not the best choice for parts that will be exposed to high temperatures.

- Brittle: Compared to other materials like ABS, PLA can be a bit more brittle and prone to cracking under stress.

- Moisture Sensitivity: PLA tends to absorb moisture from the air, which can lead to printing issues like stringing or popping. Keep it in a dry place!

Honestly, for most beginners, the pros of PLA far outweigh the cons. It’s an excellent material for learning the ropes and experimenting with different designs.

PETG: The Stronger, More Flexible Sibling

Okay, so you’ve mastered PLA and you’re looking for something a bit more robust? Polyethylene Terephthalate Glycol-modified, or PETG, might be your next best friend. It’s like PLA’s cooler, slightly tougher sibling. Seriously, this stuff is impressive.

Why PETG is a Great Next Step:

- Increased Strength and Durability: PETG is significantly stronger and more impact-resistant than PLA. It can handle more stress without breaking.

- Higher Heat Resistance: PETG can withstand temperatures up to around 80°C, making it suitable for parts that might get a bit warm.

- Good Chemical Resistance: It’s resistant to many chemicals, which expands its range of applications.

- Low Warping: Similar to PLA, PETG has minimal warping.

- Recyclable: PETG is recyclable, making it a more environmentally friendly choice.

Things to Keep in Mind with PETG:

- Higher Printing Temperature: PETG typically requires printing temperatures between 220-250°C.

- Stringing: PETG can be prone to stringing, those fine strands of plastic that connect different parts of your print. This can be mitigated with proper settings.

- Bed Adhesion: While warping is low, bed adhesion can sometimes be tricky. A good bed adhesive like glue stick or hairspray can help.

PETG bridges the gap between the ease of PLA and the strength of more advanced materials like ABS. It’s a fantastic option for functional parts or anything that needs to withstand some wear and tear.

TPU: For When You Need Flexibility

Now, let’s talk about something completely different: Thermoplastic Polyurethane, or TPU. This isn’t your rigid plastic; this is your flexible friend. TPU opens up a whole new world of 3D printing possibilities, from phone cases to flexible hinges. You know what I mean?

Why TPU is Awesome:

- Extreme Flexibility: TPU is incredibly flexible and can be bent, stretched, and compressed without breaking.

- High Impact Resistance: It can absorb significant impacts, making it great for protective parts.

- Abrasion Resistance: TPU is resistant to wear and tear, making it ideal for parts that will experience friction.

- Variety of Hardness: TPUs come in different hardness levels, ranging from very soft and rubbery to semi-rigid.

The Challenges of Printing with TPU:

- Printing Speed: TPU usually requires slower printing speeds to avoid jams and ensure good layer adhesion.

- Stringing: Like PETG, TPU can be prone to stringing.

- Filament Handling: Flexible filaments can be tricky to feed through the printer. Direct drive extruders tend to work better than Bowden extruders.

TPU might require a bit more patience and tuning, but the unique properties it offers make it well worth the effort. Imagine printing custom shoe insoles or flexible robot grippers. The possibilities are endless!

ABS: Proceed with Caution!

Acrylonitrile Butadiene Styrene, or ABS, is a common material in traditional manufacturing due to its strength and heat resistance. However, it’s generally not recommended for beginners, and here’s why.

Why ABS Can Be Tempting:

- High Strength and Durability: ABS is strong and can withstand significant stress and impact.

- High Heat Resistance: It can handle temperatures up to around 100°C, making it suitable for parts exposed to heat.

- Smooth Finish: ABS can be smoothed with acetone vapor, creating a very professional-looking finish.

Why Beginners Should Approach with Caution:

- High Printing Temperature: ABS requires high printing temperatures (around 230-260°C), which can be challenging for some printers.

- Warping: ABS is extremely prone to warping, especially with larger prints. An enclosure is almost mandatory.

- Strong Odor: ABS emits a strong, unpleasant odor when printing, which can be a health hazard in poorly ventilated areas.

- Bed Adhesion: Achieving good bed adhesion with ABS can be difficult.

Unless you’re willing to invest in a printer with an enclosure and are comfortable dealing with potential fumes and warping, it’s probably best to hold off on ABS until you have more experience.

Nylon (Polyamide): The Advanced Option

Okay, let’s touch on Nylon, or Polyamide – it’s quite the step up in the 3D printing world, honestly. People often ask about it, so let’s give you a fair warning: it’s usually considered an advanced material due to its tricky printing requirements and specific needs. It’s incredibly tough and resistant to all sorts of things, but printing it can be a bit of a headache if you’re not ready.

Why Consider Nylon?

- Exceptional Strength and Durability: Nylon is known for its high tensile strength and resistance to wear, making it perfect for functional parts that need to last.

- Chemical Resistance: Resistant to a wide range of chemicals and solvents, nylon is ideal for parts used in industrial applications.

- High Melting Point: Good wear resistance and resistance to temperature and impact.

The Challenges of Printing with Nylon:

- Moisture Absorption is a Big Problem: Nylon is extremely hygroscopic, meaning it absorbs moisture from the air like a sponge. Wet nylon leads to weak, brittle prints, so drying and storing it properly is mandatory. You’ll need a dedicated filament dryer.

- High Printing Temperatures Required: You’ll need to print at fairly high temperatures, typically between 240°C and 260°C, which can be challenging depending on your printer setup.

- Warping and Bed Adhesion Issues: Like ABS, nylon is prone to warping, so a heated bed and good bed adhesion are crucial.

Overall, Nylon offers unbeatable toughness and durability but demands very careful attention to detail and some specialized equipment. If you want to print with it anyway, be prepared for a steep learning curve and potentially some failed prints along the way.

Tips for Success: Making the Most of Your Beginner Material

No matter which material you choose, here are a few tips and tricks to ensure a smooth 3D printing experience:

- Start with Simple Models: Don’t try to print complex, intricate designs right away. Begin with simple shapes and gradually increase the complexity as you gain experience.

- Level Your Bed Properly: Bed leveling is crucial for good adhesion. Make sure your bed is properly leveled before each print.

- Use a Bed Adhesive: A good bed adhesive like glue stick, hairspray, or painter’s tape can greatly improve adhesion, especially with materials like PETG and ABS.

- Adjust Your Settings: Experiment with different printing settings like temperature, speed, and layer height to find what works best for your printer and chosen material.

- Keep Your Filament Dry: Moisture can wreak havoc on your prints. Store your filament in a dry, airtight container with desiccant packs.

- Clean Your Nozzle: A clogged nozzle can cause all sorts of problems. Clean your nozzle regularly to ensure smooth filament flow.

- Watch Your First Layers: The first few layers are the foundation of your print. Make sure they adhere well to the bed and are laid down smoothly.

- Don’t Be Afraid to Experiment: 3D printing is all about learning through trial and error. Don’t be afraid to experiment with different settings and techniques to find what works best for you.

Where to Buy Your Materials

There are countless places to buy 3D printing filaments, both online and in brick-and-mortar stores. Here are a few popular options:

- Amazon: A vast selection of filaments from various brands, often at competitive prices. Check them out here

- MatterHackers: A specialty 3D printing supplier with a wide range of filaments and excellent customer support.

- Prusa Research: Known for their high-quality printers and filaments.

- Local Hobby Shops: Support your local community and get expert advice from knowledgeable staff.

Honestly, shop around and compare prices to find the best deal. And don’t be afraid to try different brands to see which ones you like best.

Is 3D Printing Environmentally Friendly?

This is a question that comes up a lot, and it’s not a simple yes or no. On one hand, 3D printing can reduce waste by only using the material needed to create a part. On the other hand, some 3D printing materials are petroleum-based and not biodegradable. So, what’s the deal?

Well, as we discussed earlier, PLA is derived from renewable resources and is biodegradable under specific conditions. PETG is recyclable. The key is to choose your materials wisely and recycle or dispose of them responsibly.

Ultimately, 3D printing can be more environmentally friendly than traditional manufacturing methods, but it depends on how you use the technology and the materials you choose.

Troubleshooting Common Issues

Let’s face it: things don’t always go as planned. Here are some common issues you might encounter as a beginner and how to fix them:

- Warping:

- Increase bed temperature.

- Use a bed adhesive.

- Enclose your printer.

- Adjust your first layer settings.

- Stringing:

- Reduce printing temperature.

- Increase retraction distance and speed.

- Ensure filament is dry

- Adjust travel speed.

- Poor Bed Adhesion:

- Level your bed properly.

- Clean your build plate.

- Use a bed adhesive.

- Adjust your first layer settings.

- Under-Extrusion:

- Check for Clogs if the filament is having a hard time going through.

- Increase Nozzle Temperature by 5-10C.

- Reduce Print speed by 10-20%.

- Check Extruder Tension.

- Over-Extrusion:

- Lower Flow Rate.

- Check Filament Diameter is correct..

- Reduce Printing Temperature by 5-10C.

- Calibrate E-Steps.

Honestly, troubleshooting can be frustrating, but it’s also part of the learning process. Don’t give up! There are tons of resources online, like forums and tutorials, to help you solve any problem you encounter. Simplify3D’s troubleshooting guide is another great resource.

What About Resin Printing?

So far, we’ve focused on Fused Deposition Modeling (FDM) printing, which uses filaments. But there’s another type of 3D printing called resin printing, which uses liquid resins that are cured by UV light. Is resin printing a good option for beginners? Let’s find out.

The Allure of Resin Printing:

- High Resolution: Resin printing can achieve incredibly fine details and smooth surfaces that are difficult to replicate with FDM printing.

- Complex Geometries: It’s well-suited for printing intricate and complex geometries.

Why Resin Printing Might Not Be Ideal for Beginners:

- Messy: Working with liquid resins can be messy and requires gloves and proper ventilation.

- Post-Processing: Resin prints require post-processing, including washing and curing, which adds extra steps to the process.

- Cost: Resin printers and resins tend to be more expensive than FDM counterparts.

- Safety Concerns: Some resins can be toxic and require careful handling and disposal.

While resin printing offers some amazing capabilities, it’s generally not recommended for beginners due to its complexity and safety concerns. Stick with FDM printing until you’re more comfortable with the fundamentals.

Final Thoughts: Start Simple, Have Fun!

3D printing is an amazing technology that’s becoming more accessible all the time. By choosing the right materials and following a few simple tips, you can get started on your own 3D printing journey and create some truly awesome things!

Just remember to start slow, be patient, and don’t be afraid to experiment. Most importantly, have fun!

FAQ Section

Disclaimer

Always refer to the manufacturer’s guidelines and material safety data sheets (MSDS) for specific information on the material you are using.

3D printing involves potential hazards, so users should exercise caution and ensure proper ventilation when operating 3D printers. This article is intended for informational purposes only and does not constitute professional advice. Follow all safety precautions and guidelines provided by your printer and material manufacturers.

Categories

- 3D Printer (517)

- Automatic Mugs (426)

- Cleaning Appliances (504)

- Electric Bikes (214)

- Electric Scooters (456)

- Electronic Gadgets (183)

Recent Comments

Archives

Product Gallery

-

Wireless Video Baby Monitor with 2 Pcs Cam 4.3 Inch Display IR Night Vision Two Way Intercom Temperature Monitoring Babysitter

Rated 1.00 out of 5$50.00 – $115.00Price range: $50.00 through $115.00

Wireless Video Baby Monitor with 2 Pcs Cam 4.3 Inch Display IR Night Vision Two Way Intercom Temperature Monitoring Babysitter

Rated 1.00 out of 5$50.00 – $115.00Price range: $50.00 through $115.00 -

5 INCH IPS Screen Video Baby Monitor Pan Tilt 4X Zoom Camera Babysitter 2 Way Audio Night Vision 5000mAh Battery Lullaby

Rated 5.00 out of 5$70.00

5 INCH IPS Screen Video Baby Monitor Pan Tilt 4X Zoom Camera Babysitter 2 Way Audio Night Vision 5000mAh Battery Lullaby

Rated 5.00 out of 5$70.00 -

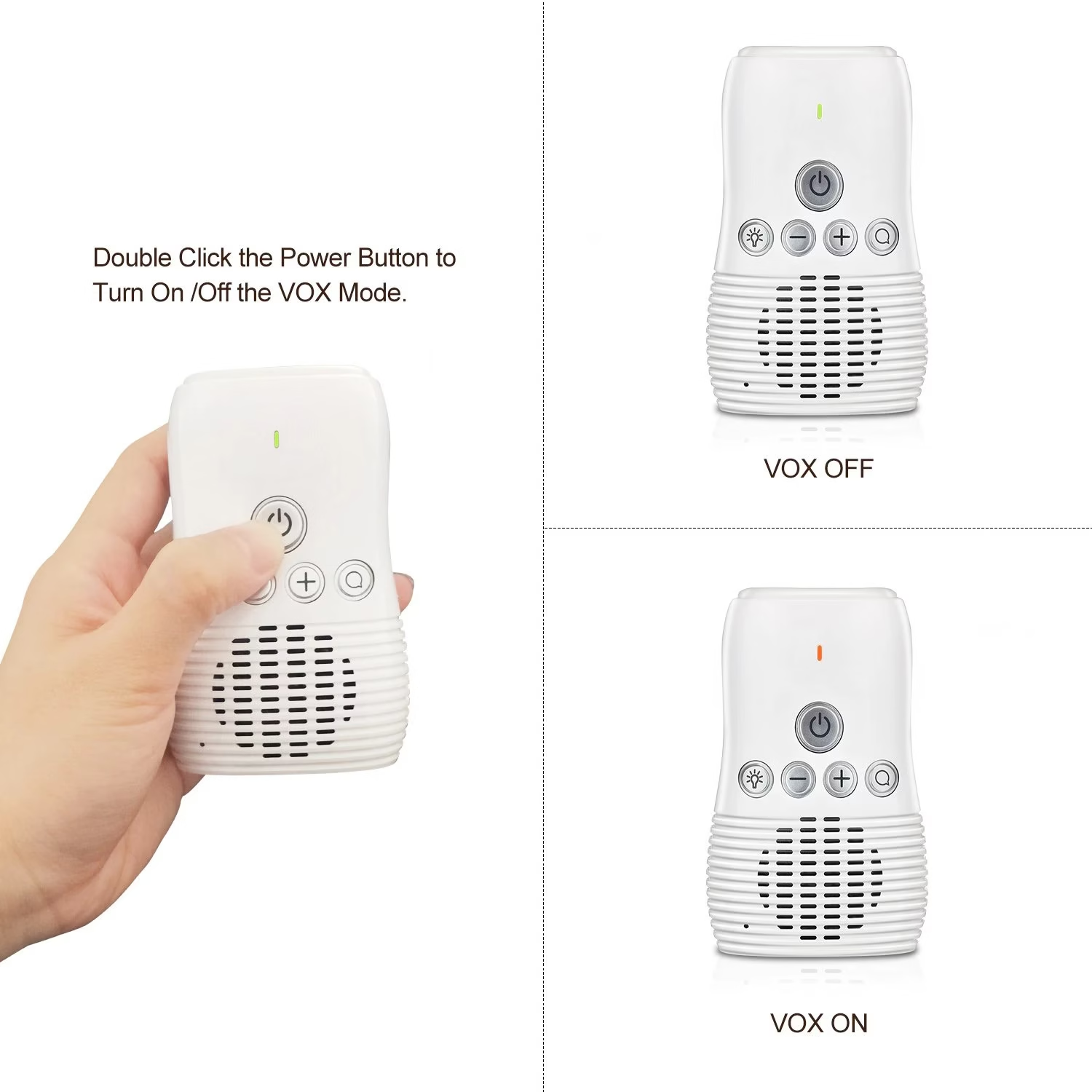

2.4Ghz Wireless Baby Monitor Small Portable Audio Baby Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 3.83 out of 5$36.00

2.4Ghz Wireless Baby Monitor Small Portable Audio Baby Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 3.83 out of 5$36.00

Robot Vacuums

Robot Vacuums Steam Cleaner

Steam Cleaner Window Robots

Window Robots

Self Stirring Mugs

Self Stirring Mugs Self Heating Mugs

Self Heating Mugs

Air Purifier

Air Purifier Dehumidifier

Dehumidifier Diffuser

Diffuser Humidifier

Humidifier

Panoramic Camera

Panoramic Camera Solar Camera

Solar Camera Window Door Sensor

Window Door Sensor Baby Monitor

Baby Monitor Small Cameras

Small Cameras

Electric Bike

Electric Bike Electric Bike Motor

Electric Bike Motor Electric Scooter

Electric Scooter Electric Skateboard

Electric Skateboard Hoverboard

Hoverboard

3D Printers

3D Printers 3D Printer Filament

3D Printer Filament