So, you’re itching to jump into the ever-expanding world of 3D printing? Awesome! It’s like having a mini-factory right on your desk. But let’s be real, all those different materials can feel overwhelming at first. Don’t sweat it! This guide will walk you through the best materials for beginners, making sure your first projects are a success (and maybe even a little fun!).

First Things First: Understanding the Basics

Before we get material-specific, let’s quickly cover some ground. 3D printing, at its heart, is about building objects layer by layer from a digital design. The most common type of 3D printing for hobbyists and beginners is Fused Deposition Modeling (FDM), where a printer melts and extrudes plastic filament. Think of it like a really precise, computer-controlled hot glue gun. We’re mainly going to focus on FDM-friendly materials here, because, well, that’s where most folks start. Other types exist, like resin printing (SLA/DLP), but those come with their own set of challenges and material considerations for later.

PLA: The King of Beginner-Friendly Filaments

PLA, or Polylactic Acid, is often the first material recommended to new 3D printers, and for good reason. It’s derived from renewable resources like cornstarch or sugarcane. You know what that means, right? It’s more eco-friendly than some alternatives. It also prints at relatively low temperatures, which makes it less prone to warping. Warping, in case you’re unfamiliar, is when the corners of your print lift off the build plate – a common headache for new users.

Why is PLA so great for beginners? Let me lay it out:

- Easy to Print: Low printing temperature (around 190-220°C) means less chance of warping and easier bed adhesion.

- Biodegradable(ish): Made from renewable resources, making it a more sustainable choice.

- Low Odor: Doesn’t release strong fumes during printing, making it ideal for home use.

- Wide Availability: You can find PLA in tons of colors and finishes pretty much anywhere that sells 3D printing stuff.

However, PLA isn’t perfect. It’s not the strongest material out there and can be brittle. It’s also sensitive to heat, which means it can soften or deform in hot environments (like a car dashboard on a sunny day). So, while it’s fantastic for figurines, prototypes, or decorative items, it might not be the best choice for parts that need to withstand high temperatures or significant stress.

ABS: When You Need Something a Little Tougher

Acrylonitrile Butadiene Styrene, or ABS, is another common 3D printing material. If PLA is the friendly, approachable neighbor, ABS is the slightly rougher, more rugged cousin. It’s the same plastic used to make Lego bricks, so you know it can handle some abuse. ABS is tougher, more heat-resistant, and more durable than PLA.

Here’s a quick rundown of what makes ABS tick:

- Higher Strength: More impact-resistant and less brittle than PLA.

- Heat Resistance: Can withstand higher temperatures without deforming, making it suitable for parts that will be exposed to heat.

- Durable: Holds up well to wear and tear.

But here’s the catch: ABS is trickier to print than PLA. It requires higher printing temperatures (around 230-260°C) and a heated bed to prevent warping. It also releases stronger fumes during printing, so you’ll want to ensure good ventilation in your workspace. Some printers, come enclosed which are excellent for using ABS.

Is it worth the hassle? Absolutely, if you need a part that’s going to see some action. Think enclosures for electronics, gears, or anything that needs to withstand a bit of stress.

PETG: The Best of Both Worlds?

Polyethylene Terephthalate Glycol-modified, or PETG, is increasingly popular, and for good reason. It’s often described as a blend of PLA and ABS, offering some of the best qualities of both. Like PLA, it’s relatively easy to print, but it’s also stronger and more heat-resistant. Sounds pretty good so far, doesn’t it?

Why might you reach for PETG? Consider these factors:

- Good Strength and Durability: Offers a good balance of strength and flexibility.

- Heat Resistance: Better heat resistance than PLA, though not as high as ABS.

- Low Warping: Less prone to warping than ABS, making it easier to print.

- Food Safe: Certain grades of PETG are food-safe, making it suitable for containers and other food-related items (but always check the manufacturer’s specifications!).

One thing to watch out for with PETG is stringing – those annoying little strands of plastic that can form between parts of your print. Careful temperature and retraction settings can usually minimize this. All in all, PETG is a versatile material that’s well worth experimenting with as you gain experience.

TPU: Getting Flexible with Your Prints

Alright, now for something completely different: Thermoplastic Polyurethane, or TPU. This is a flexible filament, meaning it can bend and stretch without breaking. Imagine printing phone cases, gaskets, or even wearable items. Cool, right?

Here’s the lowdown on TPU:

- Flexible: Can bend and stretch, making it ideal for flexible parts.

- Durable: Resistant to abrasion and wear.

- Vibration Dampening: Can absorb shocks and vibrations.

Printing with TPU can be a bit tricky at first because it’s flexible. Slow printing speeds are usually necessary to avoid jams and ensure accurate extrusion. Also, direct-drive extruder printers tend to handle TPU better than Bowden-style printers because they provide more precise control over the filament. But honestly, once you dial in the settings, the possibilities are pretty much open on what you can create.

Nylon: The Workhorse Material

Nylon is a strong, durable, and versatile material that’s used in a wide range of applications, from clothing to car parts. In 3D printing, it’s known for its high strength, abrasion resistance, and chemical resistance. So, why isn’t it higher on the list for beginners?

Here’s the deal with Nylon:

- High Strength and Durability: Very strong and resistant to wear and tear.

- Chemical Resistance: Can withstand exposure to many chemicals.

- Low Friction: Has a smooth surface and low coefficient of friction.

The challenge with nylon is that it’s very hygroscopic, meaning it absorbs moisture from the air like a sponge. This can lead to printing problems like bubbling, stringing, and poor layer adhesion. To print nylon successfully, it needs to be stored in a dry environment and dried thoroughly before printing. You also need a printer that can reach high temperatures (around 240-260°C) and a well-adhered build plate. It’s doable, but it does require a bit more effort and equipment.

A Few Extra Tips for Material Success

Okay, you’ve got a handle on the basic materials. But let’s add some finishing touches to make sure your 3D printing experience is smooth sailing.

- Start with PLA: Seriously, it’s the easiest to learn with.

- Level Your Bed: A level bed is crucial for good adhesion. Seriously, take the time to do this!

- Experiment with Settings: Learn how different settings like temperature, speed, and layer height affect your prints.

- Join a Community: Online forums and groups are a great source of information and troubleshooting advice.

- Invest on a good quality printer: A bit of initial investment on a good printer with auto bed leveling can save you a lot of time and frustration

Troubleshooting Common Issues

Let’s be honest, things don’t always go as planned in the 3D printing world. Here are a few common problems and how to tackle them:

- Warping: Increase bed temperature, use a brim or raft, and ensure your printer is in a draft-free environment.

- Poor Adhesion: Clean the build plate with isopropyl alcohol, use a bed adhesive, and make sure the nozzle is the correct distance from the bed.

- Stringing: Adjust retraction settings, lower printing temperature, and ensure the filament is dry.

- Clogging: Clean the nozzle, increase printing temperature, and try a different filament.

Don’t get discouraged! Every 3D printer has a bit of a learning curve. The more you experiment and troubleshoot, the better you’ll become. And, honestly, the satisfying feeling of pulling off a perfect print is totally worth it.

So, What’s the Verdict?

Choosing the right material is a crucial first step in your 3D printing journey. PLA is your reliable starting point, offering ease of use and versatility. As you gain confidence, explore ABS, PETG, TPU, and nylon to expand your capabilities and create more complex and functional prints. And remember, don’t be afraid to experiment and learn from your mistakes. Happy printing!

Additional Resources

Here are some more resources you can check out to enhance your knowledge about 3D printing.

FAQ Section

PLA (Polylactic Acid) is generally considered the easiest material for beginners due to its low printing temperature, minimal warping, and ease of use.

While PLA is derived from renewable resources, it’s not typically considered food safe due to potential bacterial growth in the layer lines. If you need food-safe prints, consider using a food-grade PETG and apply a food-safe sealant.

PLA typically prints well between 190°C and 220°C. Experiment within this range to find the optimal temperature for your specific printer and filament.

To prevent warping with ABS, use a heated bed (around 100-110°C), ensure good bed adhesion with adhesives like glue stick or專ABS slurry, and print in an enclosed printer to maintain a consistent temperature.

PLA is easier to print but less heat resistant and more brittle, while PETG offers better strength, heat resistance, and flexibility, with slightly more complex printing requirements.

Stringing with TPU can be caused by high printing temperatures, slow retraction speeds, or wet filament. Try lowering the temperature, increasing retraction speed and distance, and drying the filament.

While you don’t necessarily need a special printer, a direct-drive extruder is highly recommended for printing flexible filaments like TPU, as it provides better control over the filament and reduces the risk of jamming.

DISCLAIMER

3D printing involves working with heated materials and moving parts. Always exercise caution and follow safety guidelines provided by the printer and filament manufacturers. Ensure proper ventilation when printing with materials that emit fumes, and never leave a printer unattended during operation. The information provided in this article is for general guidance only, and individual results may vary. Always consult with experts and refer to specific product instructions for best results.

Categories

- 3D Printer (517)

- Automatic Mugs (426)

- Cleaning Appliances (504)

- Electric Bikes (214)

- Electric Scooters (456)

- Electronic Gadgets (183)

Recent Comments

Archives

Product Gallery

-

Wireless Video Baby Monitor with 2 Pcs Cam 4.3 Inch Display IR Night Vision Two Way Intercom Temperature Monitoring Babysitter

Rated 1.00 out of 5$50.00 – $116.00Price range: $50.00 through $116.00

Wireless Video Baby Monitor with 2 Pcs Cam 4.3 Inch Display IR Night Vision Two Way Intercom Temperature Monitoring Babysitter

Rated 1.00 out of 5$50.00 – $116.00Price range: $50.00 through $116.00 -

5 INCH IPS Screen Video Baby Monitor Pan Tilt 4X Zoom Camera Babysitter 2 Way Audio Night Vision 5000mAh Battery Lullaby

Rated 5.00 out of 5$71.00

5 INCH IPS Screen Video Baby Monitor Pan Tilt 4X Zoom Camera Babysitter 2 Way Audio Night Vision 5000mAh Battery Lullaby

Rated 5.00 out of 5$71.00 -

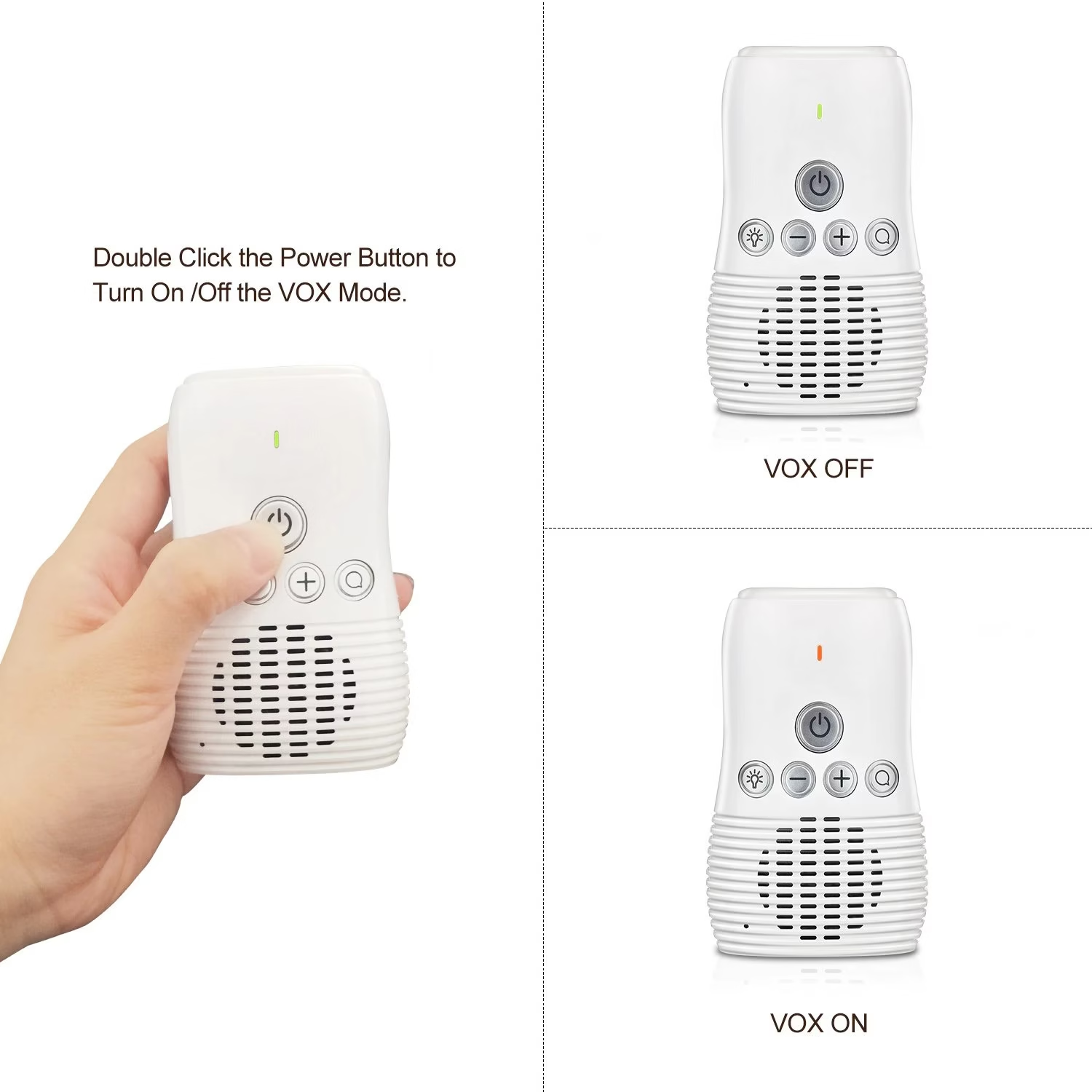

2.4Ghz Wireless Baby Monitor Small Portable Audio Baby Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 3.83 out of 5$36.00

2.4Ghz Wireless Baby Monitor Small Portable Audio Baby Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 3.83 out of 5$36.00

Robot Vacuums

Robot Vacuums Steam Cleaner

Steam Cleaner Window Robots

Window Robots

Self Stirring Mugs

Self Stirring Mugs Self Heating Mugs

Self Heating Mugs

Air Purifier

Air Purifier Dehumidifier

Dehumidifier Diffuser

Diffuser Humidifier

Humidifier

Panoramic Camera

Panoramic Camera Solar Camera

Solar Camera Window Door Sensor

Window Door Sensor Baby Monitor

Baby Monitor Small Cameras

Small Cameras

Electric Bike

Electric Bike Electric Bike Motor

Electric Bike Motor Electric Scooter

Electric Scooter Electric Skateboard

Electric Skateboard Hoverboard

Hoverboard

3D Printers

3D Printers 3D Printer Filament

3D Printer Filament