Best 3D Troubleshooting Tips For Improving First Layer Adhesion

Ah, 3D printing. It promised us a future of instant prototyping and personalized trinkets. And honestly, it delivers… most of the time. But let’s be real, we’ve all been there: watching in horror as our carefully designed masterpiece turns into a spaghetti monster on the print bed. You know, the kind of failure that makes you question all your life choices? It all boils down to that crucial first layer. Nail that, and you’re golden. Mess it up, and you’re in for a world of frustration. So, let’s tackle this head-on and get those prints sticking like they’re supposed to!

Why is First Layer Adhesion Such a Big Deal, Anyway?

Think of the first layer as the foundation of a building. If it’s not solid, the whole thing crumbles, right? Same with 3D printing. A good first layer means a strong base for subsequent layers to build upon. It ensures proper dimensional accuracy, prevents warping, and ultimately, leads to successful prints. Plus, who wants to waste filament and time on failed prints? Not me, and I’m guessing, not you either.

Getting Down to Brass Tacks: Bed Leveling and Calibration

Okay, let’s get real – this is where most of the magic happens, or doesn’t happen, as the case may be. Bed leveling, at its core, is about making sure your print bed is perfectly aligned with the nozzle. How many times have you started a print, only to see the filament barely stick in some areas and squish down way too much in others? Yeah, been there.

Manual Bed Leveling – The Old-School Approach

This is the method many of us started with, and while it might seem a tad tedious, it gives you an intimate understanding of your printer. Grab a piece of paper (yes, plain old printer paper works fine), and let’s get to it:

- The Paper Test: Move the nozzle to each corner of the bed, and the center if your printer supports it. Adjust the bed leveling knobs until you feel a slight drag on the paper when you slide it between the nozzle and the bed.

- The Feel: The key is consistency. You want that same slight drag at every point. Too much resistance, and the nozzle is too close; too little, and it’s too far.

- Patience is Key: This isn’t a one-and-done deal. You might need to go around the bed multiple times to get it just right. It’s a bit of an art, to be honest.

Automatic Bed Leveling (ABL) – The Modern Marvel

If you’re lucky enough to have a printer with ABL, count your blessings. ABL systems use sensors to map the bed’s surface and compensate for any imperfections automatically. Sounds great, right? It mostly is, but even ABL isn’t foolproof:

- Z-Offset: This is crucial. The Z-offset tells the printer how far away from the bed the nozzle should be on the first layer. Too high, and your filament won’t stick; too low, and you’ll get elephant’s foot (more on that later).

- Live Adjustments: Many printers allow you to adjust the Z-offset on the fly while the first layer is printing. Use this to fine-tune the adhesion in real-time. Keep an eye on that first layer and make small adjustments until it looks just right.

- Sensor Calibration: Periodically calibrate your ABL sensor to ensure it provides accurate readings.

Calibrating Extruder

Extrusion calibration is essentially ensuring that your 3D printer is extruding the correct amount of filament as instructed by the printer’s software. It involves adjusting the extruder’s steps per millimeter (steps/mm) value.

The process involves instructing the printer to extrude a specific length of filament (e.g., 100mm) and then measuring how much filament was actually extruded. If the measured length differs from the commanded length, the steps/mm value is adjusted accordingly to correct the extrusion rate.

You know what? I think about this process as kind of like tuning a musical instrument. You want to get each note, or in this case, each layer, to be just right. Only, instead of hitting a wrong note, you end up with a print that looks like abstract art gone wrong. I recommend checking out this guide for a more detailed walkthrough since there are just so many specific models of printers out there.

Material Matters: Choosing the Right Filament

Alright, let’s talk materials. Not all filaments are created equal, and what works for one might be a total disaster for another. The type of filament you use can significantly affect first layer adhesion. Here’s a quick rundown:

PLA – The Easygoing Option

PLA is generally the easiest to work with and sticks well to a variety of surfaces. It’s a great starting point for beginners. PLA (Polylactic Acid) is made from renewable resources like corn starch or sugarcane, making it biodegradable under the right conditions (industrial composting facilities).

- Bed Temperature: Aim for a bed temperature between 60-70°C.

- Surface: PLA sticks well to glass, painter’s tape, and PEI sheets.

- Fan: Use a cooling fan after the first few layers to prevent warping.

ABS – The Sturdy Contender

ABS is stronger and more heat-resistant than PLA, but it’s also more prone to warping. It requires a heated bed and often an enclosure to maintain consistent temperatures.

Acrylonitrile Butadiene Styrene (ABS) filament is a petroleum-based thermoplastic polymer, widely favored for its robustness and elevated temperature resistance.

- Bed Temperature: You’ll need a higher bed temperature, around 100-110°C.

- Enclosure: An enclosure helps to keep the ambient temperature consistent, reducing the risk of warping.

- Adhesion Aids: ABS juice (ABS dissolved in acetone) or glue stick can improve adhesion.

PETG – The Flexible Friend

PETG is known for its flexibility and good adhesion properties, but it can sometimes stick too well to the bed.

Polyethylene Terephthalate Glycol-modified which is a thermoplastic polymer with enhanced clarity. It is widely used across different application.

- Bed Temperature: Around 70-80°C usually does the trick.

- Surface: PETG can bond strongly to PEI sheets, so consider using a release agent like Windex or glue stick.

- Print Speed: Slow down the first layer to ensure good adhesion.

Specialty Filaments – The Wild Cards

Carbon fiber, nylon, TPU—these can all be a bit finicky. Always check the manufacturer’s recommendations for bed temperature and adhesion methods.

Honestly, it can be a bit of trial and error to dial in your settings, so don’t be afraid to experiment. And hey, keep a notebook handy—you’ll thank yourself later when you’re trying to remember what magic combo finally worked!

Surface Prep: Getting Your Bed Ready for Action

You wouldn’t start painting a wall without prepping the surface, right? Same goes for your print bed. Contaminants like oil, grease, and fingerprints can wreak havoc on adhesion. Let’s get that bed squeaky clean.

Cleaning Agents – What to Use (and What to Avoid)

- Isopropyl Alcohol (IPA): This is your best friend. A quick wipe-down with IPA before each print removes most contaminants.

- Acetone: Use this sparingly, and only on certain surfaces like glass or PEI. Acetone can damage other surfaces, so be careful.

- Dish Soap and Water: For a deep clean, wash the bed with warm, soapy water. Just make sure to dry it thoroughly before printing.

- Avoid: Harsh chemicals like bleach or ammonia-based cleaners. These can damage the bed surface.

Adhesion Aids – When You Need a Little Extra Help

Sometimes, even a clean bed isn’t enough. That’s where adhesion aids come in. Think of them as the glue that holds your 3D printing dreams together (literally).

- Painter’s Tape: A classic for PLA. It provides a textured surface that the filament can grip onto.

- Glue Stick: Works well with a variety of filaments, especially ABS and PETG. Apply a thin, even layer to the bed.

- Hair Spray: Another option for ABS. Apply a light coat to the bed before heating.

- Build Plate Adhesives: These are specifically designed for 3D printing and can provide excellent adhesion. Brands like Magigoo are popular choices.

Here’s the thing: everyone has their favorite. Some people swear by purple glue sticks, others by a specific brand of hairspray. Find what works for you and stick (pun intended) with it!

Slicing Software Secrets: Optimizing Your Settings

Your slicing software is where you translate your 3D model into instructions that your printer can understand. And, trust me, the right settings can make all the difference when it comes to first layer adhesion.

First Layer Height – Squish That Filament

The first layer height is the thickness of the initial layer. A slightly thicker first layer can improve adhesion by “squishing” the filament onto the bed.

- Experiment: Try setting your first layer height to 120-150% of your normal layer height. For example, if your layer height is 0.2mm, try a first layer height of 0.24-0.3mm.

First Layer Speed – Slow and Steady Wins the Race

Printing the first layer slowly gives the filament more time to adhere to the bed. I usually drop the first layer print to about half the normal print speed.

- Adjust: Set your first layer print speed to 20-30mm/s.

Bed Temperature and Nozzle Temperature – Finding the Sweet Spot

We talked about this earlier, but it’s worth reiterating: the right temperatures are crucial. Check your filament manufacturer’s recommendations and adjust accordingly.

- Fine-Tune: Small adjustments can make a big difference. Try increasing or decreasing the bed temperature by 5-10°C to see what works best.

Brims and Rafts – The Ultimate Safety Nets

If you’re still struggling with adhesion, brims and rafts can be lifesavers.

- Brim: A brim adds a single-layer outline around the base of your print, increasing the surface area in contact with the bed.

- Raft: A raft creates a whole new foundation for your print. It’s more wasteful than a brim, but it can be incredibly effective for difficult materials or complex geometries.

Honestly? Play around with these settings. There’s no one-size-fits-all solution, and what works for one print might not work for another. It’s all part of the fun (or frustration) of 3D printing!

Hardware Hacks: Upgrading Your Printer

Sometimes, the problem isn’t you – it’s your equipment. If you’ve tried everything else and still can’t get that first layer to stick, it might be time to consider some hardware upgrades.

Build Plate Surface – Swapping Out for Success

The surface of your build plate can make a huge difference. Here are a few popular options:

- Glass Bed: Provides a smooth, flat surface. Tempered glass is more resistant to cracking.

- PEI Sheet: Offers excellent adhesion for a wide range of materials. Flexible PEI sheets make it easy to remove prints.

- Magnetic Build Plate: Combines the benefits of a flexible PEI sheet with easy removal.

Nozzle Upgrades – Precision Matters

A worn or damaged nozzle can cause inconsistent extrusion, leading to poor adhesion. Consider upgrading to a higher-quality nozzle:

- Stainless Steel: A good all-around option.

- Hardened Steel: Necessary for abrasive filaments like carbon fiber.

- Coated Nozzles: Reduce filament buildup and improve flow.

Enclosure – Keeping the Heat In

We mentioned this earlier with ABS, but it’s worth repeating: an enclosure can make a massive difference, especially for temperature-sensitive materials.

- DIY Enclosures: You can build your own enclosure using materials like cardboard, acrylic, or even a modified storage container.

- Commercial Enclosures: These offer more features like temperature control and filtration.

I know, hardware upgrades can be a bit of an investment. But if you’re serious about 3D printing, they can be well worth it in the long run. Think of it as upgrading your tools – the better the tools, the better the results!

Troubleshooting Common Issues: When Things Go Wrong

Even with the best preparation, things can still go sideways. Let’s troubleshoot some common first layer adhesion problems.

Warping – The Bane of ABS Printing

Warping occurs when the corners of your print lift off the bed due to uneven cooling.

- Solution: Use an enclosure, increase bed temperature, apply adhesion aids, and ensure proper bed leveling.

Elephant’s Foot – The Squished First Layer

Elephant’s foot happens when the first layer is too squished, causing it to bulge out.

- Solution: Increase the Z-offset, reduce the initial layer height, and make sure the bed is properly leveled.

Gaps Between Lines – Not Enough Filament

If you see gaps between the lines of your first layer, it means the nozzle is too far from the bed or the extrusion rate is too low.

- Solution: Decrease the Z-offset, increase the extrusion multiplier, and calibrate your extruder.

Filament Not Sticking at All – Back to Basics

If the filament isn’t sticking at all, it’s usually a combination of factors.

- Solution: Clean the bed, level the bed, adjust the Z-offset, increase the bed temperature, and use an adhesion aid.

The truth is, troubleshooting 3D printing issues can feel like detective work. Don’t get discouraged! Keep experimenting, keep tweaking those settings, and you’ll eventually crack the code.

Maintenance and Best Practices: Keeping Things Smooth

Alright, you’ve got your first layer sticking perfectly – congratulations! But don’t get complacent. Maintaining your printer and following some best practices will help you keep those prints coming out flawlessly.

Regular Cleaning – A Clean Printer is a Happy Printer

Keep your printer clean, both inside and out. Dust, debris, and filament buildup can affect performance.

- Clean the Bed: Wipe it down with IPA before each print.

- Clean the Nozzle: Use a wire brush or nozzle cleaning filament to remove buildup.

- Clean the Extruder: Remove any filament debris from the extruder gears.

Firmware Updates – Staying Up-to-Date

Keep your printer’s firmware up-to-date. Manufacturers often release updates that improve performance and fix bugs.

- Check for Updates: Regularly check the manufacturer’s website for firmware updates.

- Follow Instructions: Follow the update instructions carefully to avoid bricking your printer.

Proper Filament Storage – Keeping it Dry

Filament absorbs moisture from the air, which can lead to printing issues. Store your filament in a dry place.

- Airtight Containers: Store filament in airtight containers with desiccant packs.

- Dry Boxes: Use a filament dry box to keep filament dry during printing.

Honestly, a little bit of maintenance goes a long way. Treat your 3D printer with respect, and it will reward you with countless hours of printing pleasure.

Conclusion: The First Layer is Just the Beginning

So, there you have it – a comprehensive guide to achieving perfect first layer adhesion. It might seem like a lot to take in, but trust me, it’s worth the effort. Nail that first layer, and you’ll unlock a whole new level of 3D printing success. And hey, don’t be afraid to experiment, ask questions, and learn from your mistakes. That’s all part of the journey. Now go forth and print with confidence!

FAQ Section

DISCLAIMER

The information provided in this article is for general informational purposes only. 3D printing involves certain risks, and techniques may vary depending on your equipment and materials. Always follow the manufacturer’s guidelines for your specific printer and filaments. The author and publisher are not responsible for any damage, injury, or loss resulting from the use of this information. Exercise caution and common sense when operating 3D printers.

Categories

- 3D Printer (517)

- Automatic Mugs (426)

- Cleaning Appliances (504)

- Electric Bikes (214)

- Electric Scooters (456)

- Electronic Gadgets (183)

Recent Comments

Archives

Product Gallery

-

Wireless Video Baby Monitor with 2 Pcs Cam 4.3 Inch Display IR Night Vision Two Way Intercom Temperature Monitoring Babysitter

Rated 1.00 out of 5$114.00

Wireless Video Baby Monitor with 2 Pcs Cam 4.3 Inch Display IR Night Vision Two Way Intercom Temperature Monitoring Babysitter

Rated 1.00 out of 5$114.00 -

5 INCH IPS Screen Video Baby Monitor Pan Tilt 4X Zoom Camera Babysitter 2 Way Audio Night Vision 5000mAh Battery Lullaby

Rated 5.00 out of 5$61.00

5 INCH IPS Screen Video Baby Monitor Pan Tilt 4X Zoom Camera Babysitter 2 Way Audio Night Vision 5000mAh Battery Lullaby

Rated 5.00 out of 5$61.00 -

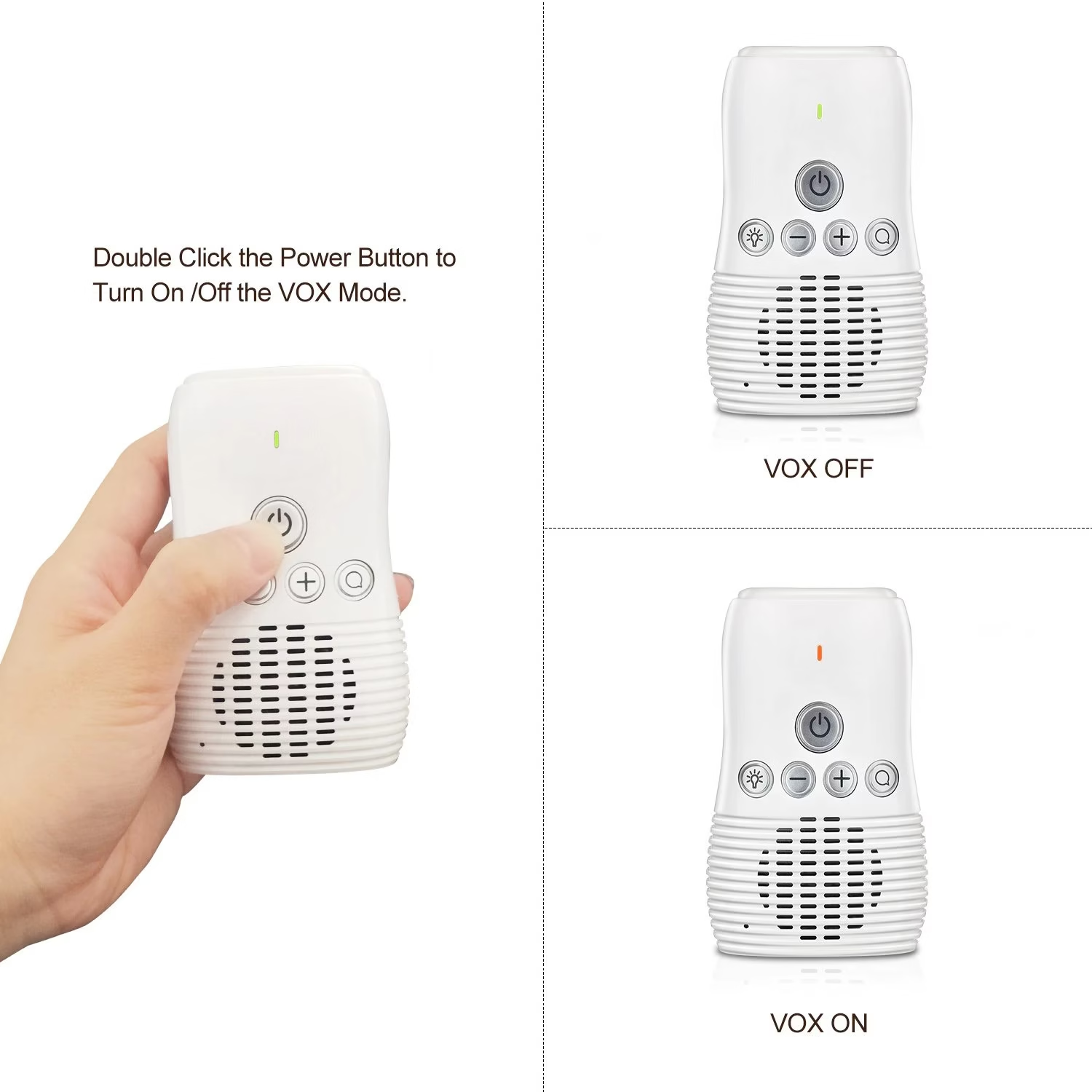

2.4Ghz Wireless Baby Monitor Small Portable Audio Baby Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 3.83 out of 5$36.00

2.4Ghz Wireless Baby Monitor Small Portable Audio Baby Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 3.83 out of 5$36.00

Robot Vacuums

Robot Vacuums Steam Cleaner

Steam Cleaner Window Robots

Window Robots

Self Stirring Mugs

Self Stirring Mugs Self Heating Mugs

Self Heating Mugs

Air Purifier

Air Purifier Dehumidifier

Dehumidifier Diffuser

Diffuser Humidifier

Humidifier

Panoramic Camera

Panoramic Camera Solar Camera

Solar Camera Window Door Sensor

Window Door Sensor Baby Monitor

Baby Monitor Small Cameras

Small Cameras

Electric Bike

Electric Bike Electric Bike Motor

Electric Bike Motor Electric Scooter

Electric Scooter Electric Skateboard

Electric Skateboard Hoverboard

Hoverboard

3D Printers

3D Printers 3D Printer Filament

3D Printer Filament