Advanced 3D Printing Techniques for Musical Instruments

Imagine holding a saxophone that’s not just made of metal, but sculpted with impossible curves, resonating with a tone unlike anything you’ve ever heard. That future, my friends, is closer than you think, thanks to the magic of advanced 3D printing. We’re not just talking about printing plastic whistles here; we’re delving into a symphony of materials, designs, and techniques that are reshaping the very definition of musical instrument creation.

The Overture: Why 3D Printing is Music to Instrument Makers’ Ears

Think about it: traditional instrument making is an art passed down through generations. It requires specialized skills, expensive tooling, and often, a whole lot of time. 3D printing, or additive manufacturing as some of the pros call it, kind of shakes things up. It lets designers bring their wildest ideas to life, experiment with funky geometries, and even customize instruments to a player’s exact specifications.

Let me explain. It’s like having a digital sculptor that can build layer upon layer, using materials ranging from plastics and metals to even ceramics. This tech opens doors to creating instruments with enhanced acoustics, ergonomic designs, and, yes, a touch of visual flair that you just can’t get with traditional methods. Take, for instance, the work being done at places like the Stratasys, where they’re exploring the boundaries of what’s possible with 3D printed materials.

Material Matters: The Palette of Possibilities

You know what’s really cool? The ever-expanding range of materials available for 3D printing.

We’re not talking about your average PLA filament here. Sure, plastics are great for prototyping and educational instruments, but advanced techniques are pushing the boundaries with:

- Metals: Titanium, stainless steel, aluminum – these bring durability and unique tonal qualities to instruments. Imagine a 3D-printed titanium trumpet!

- Resins: These allow for highly detailed and smooth surfaces, perfect for wind instruments where precise air flow is essential.

- Composites: Blending materials to achieve specific properties, like stiffness and dampening, opens up a whole new world of sonic possibilities.

- Ceramics: Offers exceptional hardness, strength, and heat resistance, ideal for applications in high-performance instruments.

Choosing the right material is crucial, honestly. It’s not just about what looks good; it’s about how the material vibrates, resonates, and ultimately contributes to the instrument’s sound. Experimentation is key, and that’s where advanced 3D printing really shines. A material like polyamide might be great for the body of a guitar, offering both strength and sonic properties, while a resin could handle delicate components like the mouthpiece of a clarinet.

Techniques that Sing: From FDM to SLS and Beyond

Okay, so we’ve talked materials. Now, let’s chat about the different 3D printing technologies in the mix. It’s not just one-size-fits-all, and each of these techniques brings different pros and cons to the table:

Fused Deposition Modeling (FDM): The Reliable Workhorse

FDM is like the trusty guitar you’ve had for years. It’s reliable, relatively inexpensive, and great for prototyping. An FDM printer works by melting a plastic filament and extruding it layer by layer to build the object. You know, it’s perfect for making prototypes, jigs, and even some parts for instruments that don’t require ultimate precision.

Stereolithography (SLA) and Digital Light Processing (DLP): Precision Personified

SLA and DLP are like the virtuoso violinists of the 3D printing world. They use light to cure liquid resin, creating incredibly detailed and smooth parts. It’s perfect for delicate components and instruments that demand high precision. Think mouthpieces, tone holes, and other intricate elements. The surface finish is usually top-notch, which means less post-processing.

Selective Laser Sintering (SLS): Powder Power

SLS uses a laser to fuse powdered materials together, layer by layer. What’s cool is that it doesn’t require support structures, so you can create complex geometries without worrying about extra cleanup. Plus, it can handle a wide range of materials, including metals and ceramics. This is game-changing for instruments that need to be both strong and lightweight.

Direct Metal Laser Sintering (DMLS): Metal Mastery

DMLS is like the heavy metal guitarist – it’s all about power and precision when it comes to printing with metals. It’s similar to SLS, but specifically tailored for metal powders. This allows you to create fully functional metal instruments with complex internal structures and intricate designs. Imagine a 3D-printed stainless steel saxophone or a titanium flute – the possibilities are endless!

Binder Jetting: Speed and Scale

Binder jetting is on the horizon, and it’s another powder-based 3D printing process in which a liquid binding agent is selectively deposited to join powder particles. As the print head moves over the build bed, it dispenses droplets of the binding agent, consolidating the powder material into a solid part. Binder jetting stands out for its rapid printing speeds and its ability to work with a diverse array of materials, including metals, ceramics, and composites. This method is particularly advantageous for producing instruments at scale, as it enables the creation of multiple objects simultaneously within the build volume. Keep an eye on this process, as it may change how instruments are mass-produced.

The choice of technique really depends on the specific instrument, the materials you’re using, and the desired level of precision. Think of it like choosing the right paintbrush for a painting – each one has its strengths and weaknesses.

Acoustic Alchemy: Designing for Sound

You can’t just print an instrument and expect it to sound amazing, right? I mean, 3D printing gives you the freedom to create any shape imaginable, but you’ve got to remember the basics of acoustics.

Let me explain further, Instrument design involves carefully manipulating how sound waves travel, vibrate, and resonate. You know, think about the bore of a wind instrument, the soundboard of a guitar, or the shape of a violin’s body. It’s not just about aesthetics; it’s about shaping the sound itself.

How to Achieve Acoustic Perfection

- Internal Structures: 3D printing makes it possible to create complex internal chambers and baffles that can fine-tune the instrument’s tone and projection.

- Variable Thickness: By varying the thickness of the material, you can control how different parts of the instrument vibrate and resonate.

- Customizable Ergonomics: Design instruments that perfectly fit the player’s hand, making them more comfortable and easier to play.

Computational modeling and simulation are key here. Software like COMSOL Multiphysics can help you predict how an instrument will sound before you even print it. That’s pretty wild! For example, you could simulate the airflow through a 3D-printed flute to optimize its intonation and tone quality. Or, you could analyze the vibrational modes of a guitar soundboard to enhance its resonance.

Post-Printing Perfection: Finishing Touches

Okay, you’ve printed your masterpiece. But the job’s not over yet! 3D-printed instruments often require some post-processing to get them ready to play.

The steps may include:

- Support Removal: Removing any support structures used during printing.

- Surface Smoothing: Sanding, polishing, or applying coatings to achieve a smooth surface finish.

- Assembly: Assembling multiple printed parts into a complete instrument.

- Tuning and Calibration: Adjusting the instrument to ensure proper intonation and playability.

The specific post-processing steps will really depend on the material and printing technology used. For example, metal parts might need to be heat-treated to relieve stress and improve their mechanical properties. Resin parts might need to be cured under UV light to fully harden them. And plastic parts might benefit from vapor smoothing to reduce layer lines.

Case Studies: Real Instruments, Real Innovation

So, who’s actually doing this stuff? The proof is in the pudding, as they say. Turns out, there are some seriously cool examples of 3D-printed instruments making waves.

The 3Dvarius Violin: A Modern Stradivarius?

The 3Dvarius is an electric violin that’s entirely 3D printed. It’s lightweight, ergonomic, and designed to resonate with exceptional clarity. Created by French violinist Laurent Bernadac, the 3Dvarius pushes the boundaries of what’s possible with 3D printing and acoustic design. According to their website, the final version of the 3Dvarius is the culmination of over 10 years of development with 5 versions and more than 50 prototypes.

ODD Guitars: Guitars That Defy Convention

ODD Guitars is known for creating wildly innovative and visually stunning 3D-printed guitars. Their designs range from minimalist and futuristic to organic and otherworldly. Each guitar is a unique work of art that showcases the potential of 3D printing to push the boundaries of instrument design.

Saxophone, Clarinet, and Flute Innovations

A number of companies and individuals are now experimenting with 3D printing to offer musical instruments to students. They are typically made of ABS plastic and can be printed in a single piece without support for a few dollars. The instruments can be printed at low-cost and high volume and are usually printed in bright colors. Replacement parts are also inexpensive to produce.

These are just a few examples, but the field is growing rapidly. As 3D printing technology continues to advance, we’ll likely see even more innovative and groundbreaking instruments emerge.

The Future of Music: What’s Next?

Honestly, the potential of these advanced techniques is mind-blowing. 3D printing could democratize instrument making, making it more accessible to students, hobbyists, and independent luthiers. Imagine a future where anyone can design and print their own custom instrument, tailored to their unique playing style and preferences.

Beyond the Horizon: Innovations to Watch For

- Multi-Material Printing: Combining different materials in a single print to achieve complex acoustic properties.

- Embedded Electronics: Integrating sensors and processors directly into the instrument for enhanced performance and interactivity.

- AI-Powered Design: Using artificial intelligence to optimize instrument designs based on acoustic simulations and player feedback.

Of course, there are challenges to overcome. 3D-printed instruments can still be more expensive than traditionally made ones, especially when using high-end materials. But as technology advances and production scales up, the costs will continue to come down. Plus, there’s a certain undeniable allure to owning an instrument that’s truly one-of-a-kind, created with cutting-edge technology.

So, what does it all mean? 3D printing is more than just a novelty in the music world. It’s a game-changer that’s already starting to redefine how instruments are designed, manufactured, and played. As the technology evolves, get ready for a whole new wave of sonic innovation.

Let’s keep the rhythm going.

Frequently Asked Questions

Ultimately, the success depends on a deep understanding of acoustics and careful design considerations to harness the potential of 3D printing effectively.

DISCLAIMER

Please be advised that experimenting with 3D printing musical instruments involves inherent risks. Ensure you have a solid understanding of both 3D printing technology and acoustic principles before embarking on any project. Always wear appropriate safety gear when operating 3D printers and handling materials. Consult with experienced professionals for complex designs or when working with potentially hazardous materials. The information provided in this article is for educational purposes only, and we assume no liability for any damages or injuries resulting from the use of this information.

Categories

- 3D Printer (517)

- Automatic Mugs (426)

- Cleaning Appliances (504)

- Electric Bikes (214)

- Electric Scooters (456)

- Electronic Gadgets (183)

Archives

About Team Ibuyem

View all posts by Team IbuyemProduct Gallery

-

Meian Smart Home Doorbell Wireless Security Doorbell IP65 Waterproof Outdoor Door Bell 60 Songs 5 Volume Adjustable Chime Kit

Rated 4.79 out of 5$13.00 – $28.00Price range: $13.00 through $28.00

-

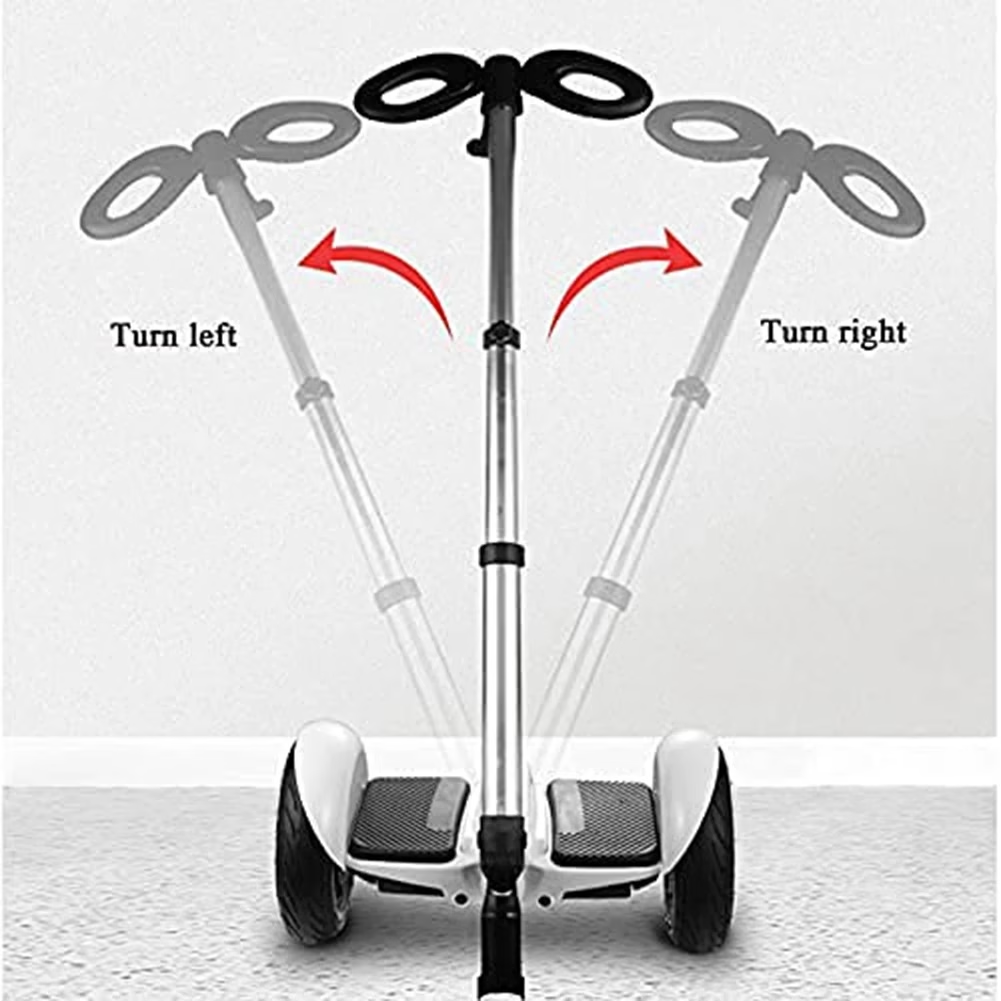

ABHS-Handlebar Suitable For Segway Ninebot Minipro Minilite Hoverboard Adjustable Three-In-One Function Pressure Handle

Rated 3.00 out of 5$61.00

ABHS-Handlebar Suitable For Segway Ninebot Minipro Minilite Hoverboard Adjustable Three-In-One Function Pressure Handle

Rated 3.00 out of 5$61.00 -

Modern Fashion 2 Wheel Smart Aluminum Hooverboard Self Balancing Scooter Kids Adults Electric Balance Scoter

$345.00

Modern Fashion 2 Wheel Smart Aluminum Hooverboard Self Balancing Scooter Kids Adults Electric Balance Scoter

$345.00

Robot Vacuums

Robot Vacuums Steam Cleaner

Steam Cleaner Window Robots

Window Robots

Self Stirring Mugs

Self Stirring Mugs Self Heating Mugs

Self Heating Mugs

Air Purifier

Air Purifier Dehumidifier

Dehumidifier Diffuser

Diffuser Humidifier

Humidifier

Panoramic Camera

Panoramic Camera Solar Camera

Solar Camera Window Door Sensor

Window Door Sensor Baby Monitor

Baby Monitor Small Cameras

Small Cameras

Electric Bike

Electric Bike Electric Bike Motor

Electric Bike Motor Electric Scooter

Electric Scooter Electric Skateboard

Electric Skateboard Hoverboard

Hoverboard

3D Printers

3D Printers 3D Printer Filament

3D Printer Filament

Recent Comments