Advanced 3D Printing Techniques for Film and TV Props

The Magic Behind the Screen: Why 3D Printing is a Game Changer

You know, for years, creating props for movies and TV shows was a painstaking process. Think of it: sculpting, molding, casting – it took forever, not to mention a ton of specialized skills. But these days? 3D printing is revolutionizing everything. It’s not just about making things faster; it’s about making the impossible possible, and doing it with incredible detail. What once took weeks can now be done in days, sometimes even hours! And honestly, that’s pretty darn amazing.

From Pixels to Props: A Quick Dive into 3D Printing Tech

Let me explain something: 3D printing, at its core, is about building objects layer by layer from a digital design. We’re talking about turning virtual blueprints into physical reality, folks! There are various methods, but a few stand out in the film and TV world:

- Fused Deposition Modeling (FDM): Think of this as a fancy hot glue gun. Plastic filament is melted and extruded, building the prop layer by layer. It’s cost-effective, perfect for larger, less detailed pieces.

- Stereolithography (SLA): This uses a liquid resin that’s hardened by a UV laser. It’s great for intricate designs and smoother surfaces. Imagine creating a highly detailed alien artifact – SLA is often the way to go!

- Selective Laser Sintering (SLS): Powdered material (like nylon or even metal) is fused together by a laser. SLS gives you strong, durable props that can withstand a bit of wear and tear.

Each technique has its strengths, and choosing the right one depends on the specific prop and its requirements. Makes sense, right?

Materials that Make the Magic: Choosing the Right Stuff

Alright, so you’ve got your 3D printer ready to roll—but what do you feed it? The materials you use matter a lot. Here’s a peek:

- PLA: A biodegradable plastic that’s easy to print with. Great for basic props that don’t need to be super strong.

- ABS: Stronger and more heat-resistant than PLA. Perfect for props that might get a little rough handling.

- Resins: Used in SLA, these offer incredible detail and smooth surfaces. Ideal for collectibles, miniatures, or anything that needs to look pristine.

- Nylon: Durable, flexible, and impact-resistant. Often used for functional parts of props that need to withstand stress.

And hey, don’t forget about composites! You can get materials infused with carbon fiber or metal for added strength and unique finishes. It’s all about finding the perfect blend of properties to bring your prop to life.

The Secret Sauce: Advanced Techniques for Film-Ready Props

Okay, here’s where it gets really interesting. It’s not just about hitting “print” and hoping for the best. Advanced techniques are what separate amateur creations from Hollywood-caliber props.

High-Resolution Printing: Capturing Every Tiny Detail

Want your prop to look like it came straight out of a blockbuster? High-resolution printing is key. This means using printers that can lay down super-fine layers, capturing every nook, cranny, and subtle texture.

Think about those incredibly detailed Star Wars helmets. To replicate something like that, you’d need a printer capable of resolutions down to 25 microns or even lower. The finer the resolution, the smoother the surface and the more realistic the final product.

Multi-Material Printing: Blending Form and Function

Why settle for one material when you can use several? Multi-material printing allows you to combine different plastics, resins, or even metals within a single print. It’s like having a Swiss Army knife for prop creation!

For example, you could print a prop gun with a rigid body and a flexible trigger, all in one go. Or create a helmet with a hard outer shell and a soft, comfortable inner lining. Talk about next-level realism, you know?

Support Structures? Not Today! Optimized Design and Orientation

One of the biggest headaches with 3D printing is support structures – those extra bits of material that hold up overhanging parts during printing. They’re a pain to remove and can leave ugly marks.

Clever designers, however, can minimize or even eliminate the need for supports by carefully orienting the model on the print bed. It’s like playing Tetris with your prop to find the perfect angle. Furthermore, using advanced algorithms to generate optimized, easily removable supports is becoming more common.

Hybrid Manufacturing: Marrying 3D Printing with Traditional Methods

Who says you have to choose between 3D printing and traditional techniques? Hybrid manufacturing combines the best of both worlds.

Imagine 3D printing a complex core for a prop and then wrapping it in carbon fiber using traditional molding techniques. Or using a 3D-printed mold to cast a metal component. This approach allows you to leverage the speed and design freedom of 3D printing while still benefiting from the strength and finish of traditional methods.

Post-Processing Perfection: From Print to Polished Prop

Alright, you’ve got your 3D-printed prop. Now what? Well, unless you’re going for a distinctly “3D-printed” look (which, hey, sometimes works!), you’ll need to do some post-processing. Here’s the rundown:

- Support Removal: Get rid of those pesky support structures! Tools like pliers, cutters, and sandpaper are your friends here.

- Sanding: Smooth out those layer lines. Start with coarse sandpaper and gradually move to finer grits. Wet sanding can also help.

- Priming: Apply a few coats of primer to create a smooth, even surface for painting.

- Painting: Go wild with color! Use airbrushes for fine details or good old-fashioned brushes for larger areas. Weathering techniques (like washes and dry brushing) can add realism.

- Assembly: Put all the pieces together! Use glue, screws, or whatever works best for your prop.

And you know what? Don’t underestimate the power of a good clear coat. It’ll protect your paint job and give your prop a professional finish.

Real-World Examples: 3D Printing in Action on Screen

So, where have you seen 3D printing in action? Honestly, it’s everywhere!

- Marvel Movies: From Iron Man’s armor to intricate weapon designs, 3D printing has been instrumental in bringing these characters to life.

- Star Wars: Did you know elements of the newer Star Wars trilogies used 3D-printed components for droids and props? Yep, that’s how they get that hyper-realistic look.

- Game of Thrones: Even in a world of dragons and medieval castles, 3D printing played a role in creating detailed set pieces and ornate props.

The possibilities are truly endless. As technology improves, we’ll see even more innovative uses of 3D printing in film and TV.

The Future is Now: What’s Next for 3D-Printed Props?

Okay, so what’s on the horizon? A few things that have me excited:

- Faster Printing Speeds: Imagine printing full-scale props in a matter of hours. New technologies are making this a reality.

- Advanced Materials: Self-healing plastics? Color-changing filaments? The material science is getting wild!

- AI-Powered Design: AI can help optimize prop designs for 3D printing, making them stronger, lighter, and easier to produce.

Honestly, it feels like we’re just scratching the surface of what’s possible. Who knows? Maybe one day we’ll be 3D printing entire movie sets!

Practical Tips: Getting Started with 3D Printing for Props

Alright, inspired yet? Want to give this a shot yourself? Here are some tips:

- Start Small: Don’t try to print a full-size replica of the Millennium Falcon right away. Start with smaller, simpler projects to get the hang of it.

- Do Your Research: There are tons of resources online—tutorials, forums, and communities dedicated to 3D printing for props.

- Invest in Good Software: You’ll need CAD software to design your props. Blender is a popular free option, while ZBrush is great for sculpting detailed models.

- Don’t Be Afraid to Experiment: 3D printing is all about trial and error. Don’t get discouraged if your first few prints aren’t perfect.

And hey, remember to have fun! It’s all about bringing your creative vision to life.

Cost Considerations: Is 3D Printing Economical?

Let’s talk money. Is 3D printing for props cost-effective? Well, it depends.

- Initial Investment: 3D printers can range from a few hundred to tens of thousands of dollars. Choose a printer that fits your budget and needs.

- Material Costs: Filament and resin prices vary, but it’s generally cheaper to print in bulk.

- Labor Costs: 3D printing can save on labor compared to traditional methods, but you’ll still need to factor in design time, post-processing, and assembly.

Overall, 3D printing can be very economical, especially for complex or custom props. Plus, the ability to iterate quickly and make changes on the fly can save time and money in the long run.

Safety First: Handling Materials and Equipment Responsibly

One last thing: safety! 3D printing involves hot equipment, chemicals, and sometimes even potentially hazardous materials.

- Ventilation: Make sure you have good ventilation when printing with materials that emit fumes.

- Eye Protection: Wear safety glasses when working with tools or handling chemicals.

- Gloves: Protect your hands from hot surfaces and chemicals.

- Read the Manuals: Seriously, read the manuals for your printer and materials. They contain important safety information.

A little caution can go a long way in preventing accidents and ensuring a safe and enjoyable 3D printing experience.

Troubleshooting Common Issues: What To Do When Things Go Wrong

3D printing isn’t always smooth sailing. Sometimes you’ll hit snags, but don’t fret! Here are some common issues and how to tackle them:

- Warping: This happens when the first layer of your print doesn’t stick properly to the bed. Try using a heated bed, applying adhesive (like glue stick), or adjusting your bed leveling.

- Stringing: This is when fine strands of plastic are left between different parts of your print. Increase retraction settings in your slicing software or lower your printing temperature.

- Clogging: This happens when filament gets stuck in the nozzle. Try cleaning the nozzle with a needle or performing a “cold pull.”

Also, the internet is brimming with troubleshooting guides and forums! A quick search can often yield solutions to even the most perplexing problems.

Resources and Tools: Where to Find Models and Software

Need some inspiration or the right tools? Here’s a quick rundown:

- Thingiverse & Cults3D: Vast libraries of 3D models, many of which are free. (Thingiverse)

- MyMiniFactory: Curated selection of guaranteed-to-print models.

- Tinkercad: A free, beginner-friendly CAD software for creating basic designs.

- Blender: A powerful, free, open-source 3D creation suite for more advanced modeling.

- Simplify3D & Cura: Popular slicing software to prepare your models for printing.

With these resources, you’ll be well-equipped to embark on your 3D printing journey!

Wrapping Up: 3D Printing – The Future of Film and TV Props?

Honestly, that’s where we’re at. 3D printing isn’t just a fad; it’s a fundamental shift in how we create props for film and television. It’s faster, cheaper, and more versatile than traditional methods—and it’s only going to get better. So, whether you’re a seasoned propmaster or just a curious enthusiast, now’s the time to get involved. The future of movie magic is being printed, one layer at a time.

FAQ Section

Disclaimer

Please note that 3D printing can involve the use of equipment and materials that require careful handling and adherence to safety guidelines. It is important to consult with professionals and conduct thorough research before engaging in any 3D printing activities. The information provided in this article is for informational purposes only, and the author and publisher are not responsible for any damages or injuries resulting from the use of 3D printing equipment or materials. Always prioritize safety and follow manufacturer guidelines.

Categories

- 3D Printer (517)

- Automatic Mugs (426)

- Cleaning Appliances (504)

- Electric Bikes (214)

- Electric Scooters (456)

- Electronic Gadgets (183)

Archives

About Team Ibuyem

View all posts by Team IbuyemProduct Gallery

-

Meian Smart Home Doorbell Wireless Security Doorbell IP65 Waterproof Outdoor Door Bell 60 Songs 5 Volume Adjustable Chime Kit

Rated 4.79 out of 5$9.07 – $20.28Price range: $9.07 through $20.28

-

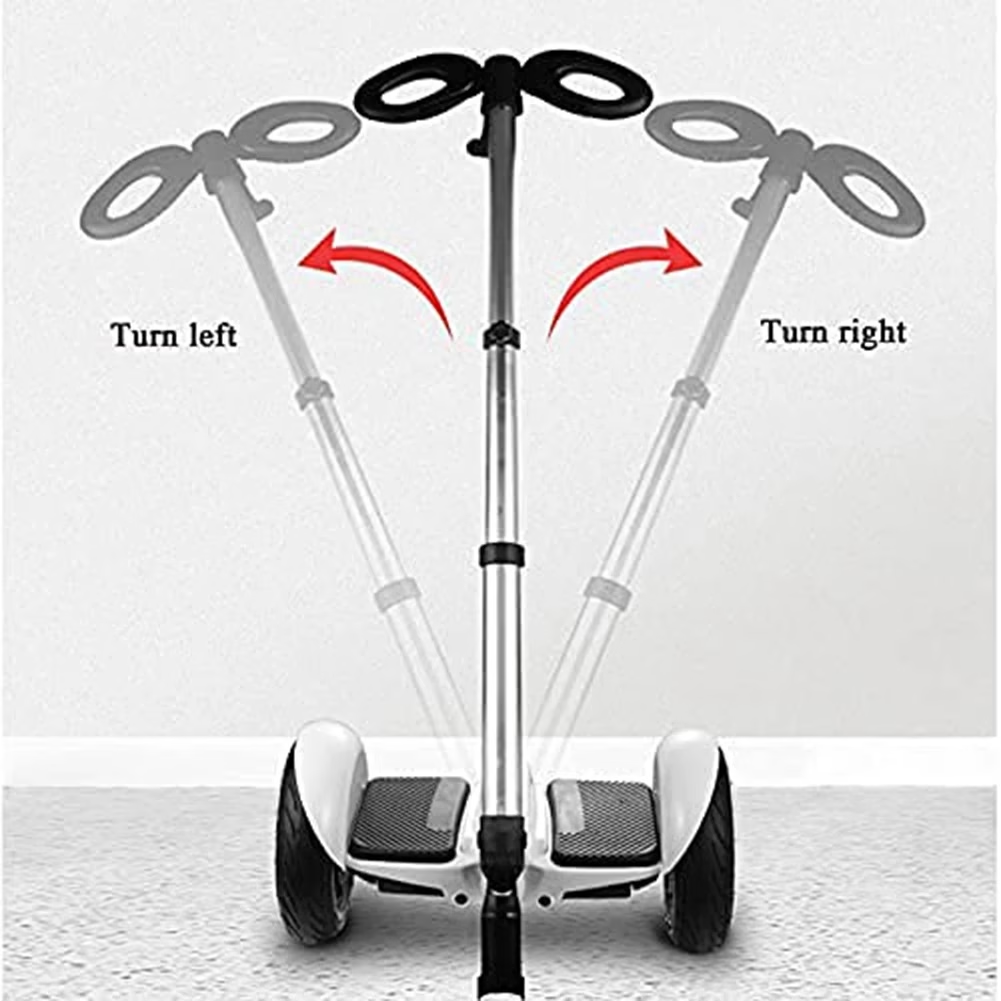

ABHS-Handlebar Suitable For Segway Ninebot Minipro Minilite Hoverboard Adjustable Three-In-One Function Pressure Handle

Rated 2.40 out of 5$43.81

ABHS-Handlebar Suitable For Segway Ninebot Minipro Minilite Hoverboard Adjustable Three-In-One Function Pressure Handle

Rated 2.40 out of 5$43.81 -

Modern Fashion 2 Wheel Smart Aluminum Hooverboard Self Balancing Scooter Kids Adults Electric Balance Scoter

$238.89

Modern Fashion 2 Wheel Smart Aluminum Hooverboard Self Balancing Scooter Kids Adults Electric Balance Scoter

$238.89

Robot Vacuums

Robot Vacuums Steam Cleaner

Steam Cleaner Window Robots

Window Robots

Self Stirring Mugs

Self Stirring Mugs Self Heating Mugs

Self Heating Mugs

Air Purifier

Air Purifier Dehumidifier

Dehumidifier Diffuser

Diffuser Humidifier

Humidifier

Panoramic Camera

Panoramic Camera Solar Camera

Solar Camera Window Door Sensor

Window Door Sensor Baby Monitor

Baby Monitor Small Cameras

Small Cameras

Electric Bike

Electric Bike Electric Bike Motor

Electric Bike Motor Electric Scooter

Electric Scooter Electric Skateboard

Electric Skateboard Hoverboard

Hoverboard

3D Printers

3D Printers 3D Printer Filament

3D Printer Filament

Recent Comments