How To Troubleshoot And Replace A Faulty Thermistor

Ever had your HVAC system acting up, or maybe your car’s engine temperature gauge is doing a jig? Chances are, a little component called a thermistor might be the culprit. These unsung heroes are crucial in various devices, from keeping your home cozy to ensuring your car doesn’t overheat. In this guide, we’ll walk you through the nitty-gritty of troubleshooting and replacing a faulty thermistor. Trust me, it’s not as daunting as it sounds!

What Exactly is a Thermistor, Anyway?

Let’s break it down. A thermistor is essentially a type of resistor whose resistance varies significantly with temperature. That’s it! The name is a mashup of “thermal” and “resistor,” which pretty much sums up what it does. If you think of a resistor as a gate controlling the flow of electricity like a dam controls water flow, then the thermistor’s gate adjusts based on temperature.

Now, there are two main types: Negative Temperature Coefficient (NTC) and Positive Temperature Coefficient (PTC) thermistors. NTC thermistors decrease in resistance as temperature increases—hotter means less resistance. PTC thermistors do the opposite; as temperature rises, so does their resistance. This difference in behavior is key to their varied applications, like temperature sensing, overcurrent protection, and even controlling heating elements. You know what? It’s kind of like how some people get more relaxed in the heat (NTC), while others get all worked up (PTC)!

Why Do Thermistors Go Bad?

Like any component, thermistors aren’t immune to the ravages of time and operational stress. Several factors can contribute to their demise. Honestly, they’re usually pretty reliable, but you’ve got to watch out for these issues:

- Overheating: Excessive temperatures can degrade the thermistor material, causing a permanent shift in its resistance characteristics.

- Moisture Intrusion: Corrosion from moisture can alter the resistance or create a short circuit.

- Physical Damage: Cracks or breaks from physical stress can outright ruin the thermistor.

- Electrical Overstress: Surges or spikes in voltage can cause the thermistor to fail catastrophically.

- Age and Use: Over time, the thermistor material can simply degrade, leading to inaccurate readings.

Essentially, a thermistor’s lifespan—and I guess that’s true for all of us—is determined by how well it’s treated and the conditions it endures. Harsh environments and operational abuse can shorten its life considerably.

Spotting the Troublemaker: Common Symptoms of a Faulty Thermistor

Alright, so how do you know if your thermistor is waving the white flag? Here are some telltale signs that something’s amiss:

- Inaccurate Temperature Readings: This is the big one. If your temperature gauge is consistently displaying wildly incorrect values, suspect the thermistor.

- Erratic Equipment Behavior: Is your HVAC system cycling on and off too frequently? Or maybe your engine is running rough? A faulty thermistor can cause all sorts of weirdness.

- Complete System Failure: In some cases, a bad thermistor can bring the whole system down. For example, in a car, it might prevent the engine from starting.

- Physical Damage: Obvious signs like cracks, breaks, or corrosion are dead giveaways.

Here’s the thing, though: these symptoms can also be indicative of other problems. So, before you go ripping out your thermistor, it’s wise to do some proper troubleshooting.

Time for Detective Work: Troubleshooting a Thermistor

Okay, Sherlock, let’s get down to brass tacks. Troubleshooting a thermistor involves a methodical approach to isolate the component and verify its functionality. Here’s how you do it:

- Visual Inspection: Start with a good old visual check. Look for any signs of physical damage, corrosion, or discoloration. If it looks fried, it probably is.

- Location, Location, Location: Find out where the Thermistor is located. It could be attached to the block of the engine, near the HVAC Unit or a PC Board. Consulting the device’s service manual is invaluable if available; otherwise, use online resources or ask experts.

- Resistance Measurement: This is where a multimeter comes in handy. Disconnect the thermistor from the circuit. Set your multimeter to measure resistance, and then measure the resistance across the thermistor’s terminals. Compare your reading to the expected value at the current temperature, which you can usually find in the device’s technical specifications or a datasheet.

- Temperature Response Test: If the resistance seems okay at room temperature, try varying the temperature and see if the resistance changes accordingly. You can use a hairdryer (carefully!) to increase the temperature or an ice pack to lower it. Monitor the resistance change; if it’s erratic or non-existent, the thermistor is likely faulty.

- Check Wiring and Connections: Sometimes, the problem isn’t the thermistor itself, but the wiring connected to it. Make sure the connections are clean and tight. Corrosion or loose connections can cause inaccurate readings.

Alright, quick digression. You know why I love troubleshooting? It’s like a puzzle. I remember back in college, I had this old car—a real beater. The engine would overheat all the time. Turns out, it wasn’t the radiator or the water pump; it was a corroded wire connected to the thermistor. A little bit of cleaning, and she ran like a champ again. Honestly, sometimes it’s the simple things!

Gathering Your Gear: Tools and Materials You’ll Need

Before you start tearing things apart, make sure you have all the necessary tools and materials. Here’s what you’ll need:

- New Thermistor: Obviously! Make sure it’s the correct type and rating for your application. Check the device’s technical specifications.

- Screwdrivers: A set of screwdrivers with various head types (Phillips, flathead, etc.) to remove any screws holding the thermistor in place.

- Multimeter: To test the old thermistor and verify the new one is working correctly. A multimeter is a versatile tool and can be used for electronics!

- Wire Strippers/Crimpers: For preparing and connecting wires if the thermistor needs to be wired in.

- Soldering Iron and Solder (If Applicable): If the thermistor is soldered to a circuit board, you’ll need these to remove the old one and install the new one.

- Heat Shrink Tubing or Electrical Tape: To insulate any exposed wire connections.

- Pliers: For gripping and manipulating small parts.

- Socket Set/Wrenches: Might be needed for removing brackets or housings around the thermistor.

- Safety Glasses: Always protect your eyes, especially when working with electronics.

- Gloves: To protect your hands and provide a better grip.

- Service Manual or Wiring Diagram: Essential for identifying the thermistor’s location and understanding the wiring.

Having the right tools not only makes the job easier but also safer. Trust me, nothing’s worse than stripping a screw because you used the wrong screwdriver. Been there, done that! A good toolbox is an investment that pays for itself over and over.

Let’s Get to Work: Step-by-Step Thermistor Replacement

Alright, with our tools in hand, let’s replace that faulty thermistor! Follow these steps carefully:

- Safety First: Disconnect Power: Before you do anything, make sure to disconnect the power to the device you’re working on. This is crucial to prevent electrical shock. Remove the plug or turn off a circuit breaker.

- Access the Thermistor: Remove any panels, covers, or components that are blocking access to the thermistor. Refer to your service manual for guidance.

- Disconnect the Old Thermistor: Depending on the application, the thermistor might be connected with wires, plugs, or soldered directly to a circuit board. Carefully disconnect it. If wired, take note of the wiring configuration or snap a photo for reference.

- Remove the Old Thermistor: If the thermistor is held in place with a bracket or clip, remove it. If it’s soldered, use a soldering iron to melt the solder and gently remove the thermistor.

- Install the New Thermistor: Place the new thermistor in the same location as the old one. If you have a brand new Thermistor, you can simply attach the wired to the appropriate slots.

- Connect the New Thermistor: Reconnect the wires or plug, matching the original configuration. If soldering, carefully solder the new thermistor to the circuit board. Ensure the solder joints are clean and solid.

- Secure and Insulate: Secure the thermistor with any brackets or clips. Insulate any exposed wire connections with heat shrink tubing or electrical tape.

- Reassemble and Test: Reinstall any panels, covers, or components you removed. Reconnect the power and test the device to ensure the new thermistor is working correctly and that the symptoms are gone.

Pro tip: Take your time. Rushing can lead to mistakes, and mistakes can lead to frustration. Take a break if you need to. It’s not a race!

What Could Possibly Go Wrong? Common Pitfalls to Avoid

Even with the best intentions, things can go sideways. Here are some common mistakes to watch out for:

- Incorrect Thermistor Type: Using the wrong type of thermistor (NTC vs. PTC) or the wrong resistance value can cause all sorts of problems. Always double-check the specifications.

- Poor Soldering: Cold solder joints can cause intermittent connections or complete failure. Make sure your solder joints are shiny and well-formed.

- Damaged Wiring: Stripping wires too aggressively or crimping them incorrectly can damage the conductors, leading to unreliable connections.

- Forgetting the Polarity: Some thermistors (especially those with integrated circuits) have a specific polarity. Connecting them backward can fry them.

- Neglecting Heat Dissipation: Some thermistors generate heat. Make sure they have adequate ventilation to prevent overheating.

Honestly, the biggest mistake I see people make is not doing their homework. Read the service manual, watch some videos, and understand what you’re doing before you start. A little preparation goes a long way.

After the Swap: Testing and Verification

Once you’ve replaced the thermistor, it’s crucial to verify that it’s working correctly. Otherwise, you’re just guessing! Here’s how to do it:

- Resistance Check: Use your multimeter to measure the thermistor’s resistance at room temperature and compare it to the expected value.

- Temperature Response Test: Vary the temperature and monitor the resistance change. It should respond smoothly and predictably.

- System Test: Run the device through its normal operating cycles and observe its behavior. Make sure the temperature readings are accurate and the system is functioning as expected.

If everything checks out, congratulations! You’ve successfully replaced your thermistor. If not, go back and double-check your connections and settings. It’s also possible the new thermistor is faulty (it happens!).

Alternative Solutions: When to Call a Professional

Sometimes, even with the best DIY spirit, you might run into situations where it’s best to call in the pros. Here are a few scenarios:

- Complex Circuitry: If the thermistor is part of a complex circuit board, and you’re not comfortable soldering or working with electronics, it’s best to leave it to the experts.

- System Warranty: Replacing the thermistor yourself might void the warranty on your device. Check the warranty terms before proceeding.

- Uncertainty: If you’re not sure what you’re doing or you’re uncomfortable working with electricity, don’t risk it. Call a qualified technician.

Honestly, there’s no shame in admitting defeat. Sometimes, it’s just not worth the hassle or the risk. A professional technician can diagnose the problem quickly and accurately, and they have the tools and expertise to get the job done right. It might cost you a bit more upfront, but it can save you a lot of headaches (and potentially more expensive repairs) in the long run.

A Few Parting Thoughts: Maintenance and Prevention

Once you’ve got your thermistor sorted, you’ll want to keep it, and other related components, happy and healthy. Here are some tips:

- Regular Inspections: Periodically check for signs of damage or corrosion. Catching problems early can prevent more serious issues down the road.

- Proper Ventilation: Ensure adequate airflow around the thermistor to prevent overheating.

- Surge Protection: Use surge protectors to protect your devices from voltage spikes.

- Follow Manufacturer’s Recommendations: Adhere to the manufacturer’s maintenance schedule and guidelines.

You know what? Prevention is always better than cure. A little bit of care and attention can extend the lifespan of your thermistors (and your equipment) significantly.

FAQ

A thermistor is a type of resistor whose resistance changes significantly with temperature. It’s used in various applications to sense temperature, control heating elements, or provide overcurrent protection.

Common symptoms include inaccurate temperature readings, erratic equipment behavior, or complete system failure. You can also visually inspect the thermistor for physical damage or corrosion.

Yes, if you have some basic tools, technical knowledge, and are comfortable working with electronics. Follow a detailed step-by-step guide and take necessary safety precautions.

You’ll need a new thermistor, screwdrivers, a multimeter, wire strippers/crimpers, a soldering iron (if applicable), heat shrink tubing or electrical tape, pliers, and a service manual or wiring diagram.

Avoid using the incorrect thermistor type, poor soldering, damaged wiring, forgetting the polarity, or neglecting heat dissipation. Always double-check specifications and follow the service manual.

If you’re not comfortable working with electronics, if the thermistor is part of a complex circuit, or if replacing it yourself might void the warranty, it’s best to call a qualified technician.

You can purchase replacement thermistors from electronic component suppliers like Digi-Key Digi-Key. Make sure to verify the specifications before purchasing.

DISCLAIMER

This guide provides general information on troubleshooting and replacing thermistors. Always consult the device’s service manual and follow safety precautions when working with electronics. The author is not responsible for any damages or injuries resulting from the use of this information.

Categories

- 3D Printer (517)

- Automatic Mugs (426)

- Cleaning Appliances (504)

- Electric Bikes (214)

- Electric Scooters (456)

- Electronic Gadgets (183)

Archives

About Team Ibuyem

View all posts by Team IbuyemProduct Gallery

-

Meian Smart Home Doorbell Wireless Security Doorbell IP65 Waterproof Outdoor Door Bell 60 Songs 5 Volume Adjustable Chime Kit

Rated 4.79 out of 5$13.00 – $28.00Price range: $13.00 through $28.00

-

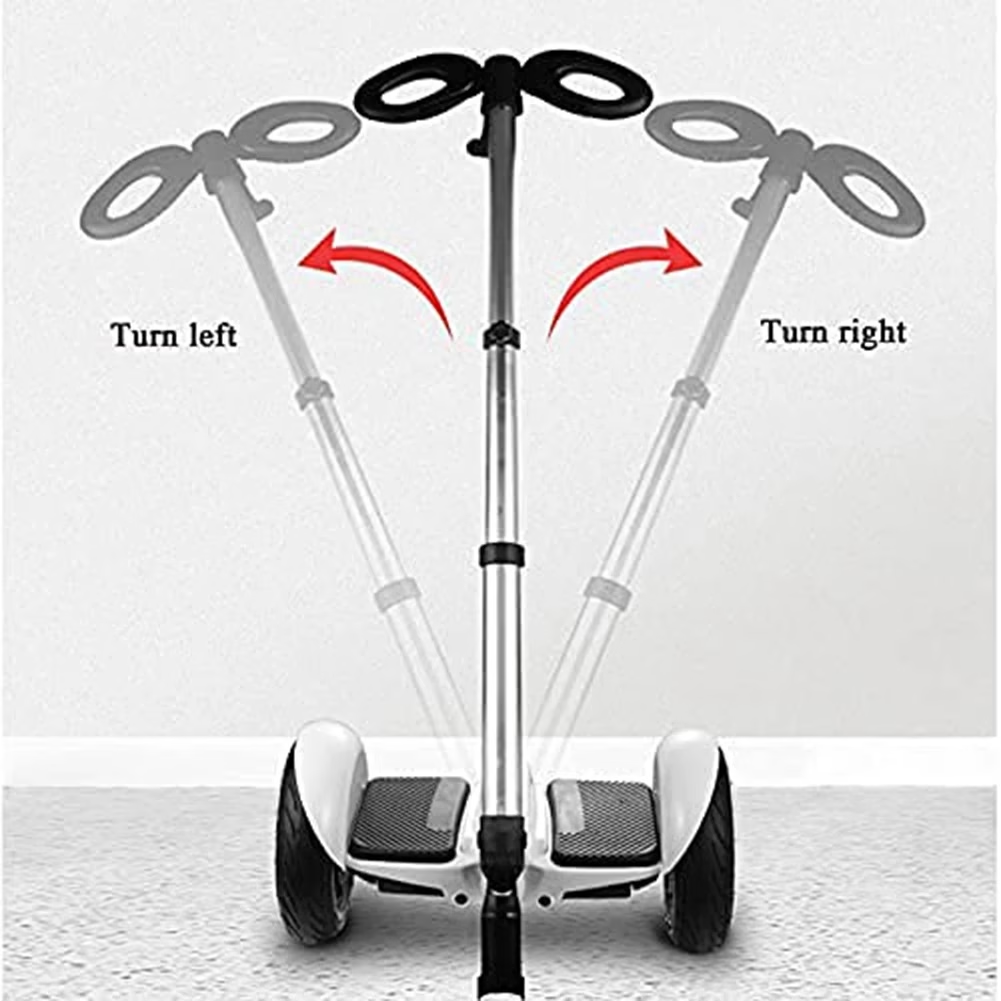

ABHS-Handlebar Suitable For Segway Ninebot Minipro Minilite Hoverboard Adjustable Three-In-One Function Pressure Handle

Rated 3.00 out of 5$61.00

ABHS-Handlebar Suitable For Segway Ninebot Minipro Minilite Hoverboard Adjustable Three-In-One Function Pressure Handle

Rated 3.00 out of 5$61.00 -

Modern Fashion 2 Wheel Smart Aluminum Hooverboard Self Balancing Scooter Kids Adults Electric Balance Scoter

$345.00

Modern Fashion 2 Wheel Smart Aluminum Hooverboard Self Balancing Scooter Kids Adults Electric Balance Scoter

$345.00

Robot Vacuums

Robot Vacuums Steam Cleaner

Steam Cleaner Window Robots

Window Robots

Self Stirring Mugs

Self Stirring Mugs Self Heating Mugs

Self Heating Mugs

Air Purifier

Air Purifier Dehumidifier

Dehumidifier Diffuser

Diffuser Humidifier

Humidifier

Panoramic Camera

Panoramic Camera Solar Camera

Solar Camera Window Door Sensor

Window Door Sensor Baby Monitor

Baby Monitor Small Cameras

Small Cameras

Electric Bike

Electric Bike Electric Bike Motor

Electric Bike Motor Electric Scooter

Electric Scooter Electric Skateboard

Electric Skateboard Hoverboard

Hoverboard

3D Printers

3D Printers 3D Printer Filament

3D Printer Filament

Recent Comments