Troubleshooting Common Issues In Materials & Filament Guides 22

So, you’re embarking on a 3D printing adventure, huh? That’s fantastic! But let’s get real for a sec: it isn’t always smooth sailing. One of the trickiest parts of 3D printing, especially for beginners, is getting your materials and filament guides to cooperate. Think of it like this: your printer is a finely tuned instrument, and your filament is the string section. If they’re not in harmony, you’re in for a cacophony of failed prints and frustration.

But don’t sweat it! We’re here to guide you through the common pitfalls and help you fine-tune your setup. From dealing with tangled filaments to understanding exotic materials, we’ve got your back. Ready to turn those headaches into “aha!” moments? Let’s jump in!

The Tangled Web: Understanding Filament Issues

Picture this: You’re halfway through a massive print, feeling good, and then BAM! Your printer stops. You rush over, only to find your filament tangled worse than a Christmas tree light convention. We’ve all been there, suffering filament tangle. What caused this nightmare?

More often than not, it’s poor spooling from the manufacturer or mishandling on your part. Filament overlapping on the spool can create a knot that tightens as the printer pulls more filament. Honestly, it’s infuriating, but thankfully, preventable.

How to Stop the Tangled Mess?

- Proper Storage: Store your filament in a dry, airtight container, like a resealable bag with desiccant packs to wick away moisture. Moisture makes filament brittle and prone to snapping, which exacerbates tangles.

- Careful Unspooling: When you remove the filament from its packaging, make sure the end is secured. Use the spool’s designated holes or clips, or even a simple piece of tape. Just don’t let it unravel like your sanity during a long print!

- Spool Management: Keep an eye on your spool while printing. Ensure that it unwinds smoothly, without any hitches. If you see a potential tangle forming, pause the print and carefully unwind the filament to resolve it.

Think of filament as a delicate thread – treat it with care. Now, let’s move on to another common headache: blockages.

Clogs and Jams: Clearing the Filament Path

Clogs in your hot end are another common foe, and they’re just as irritating as a tangled spool. A clog is when your filament gets stuck inside the nozzle or heat break, preventing it from extruding properly.

Several factors can cause this: incorrect temperature settings, debris in the filament, or even residue buildup in the nozzle over time. It’s like when your garden hose gets blocked with leaves – nothing comes through!

Why is Nothing Coming Out? Identifying the Culprit

- Temperature Troubles: Every filament type has its ideal temperature range. Printing PLA too cool can cause it to solidify before it exits the nozzle. Printing ABS too hot can cause it to bubble and clog the nozzle from the inside. Always consult the manufacturer’s recommendations.

- Dirty Filament: Dust and debris can accumulate on your filament spool over time. This gunk gets dragged into the hot end, where it can carbonize and cause a blockage. Use a filament cleaner, like a sponge attached to the filament path, to wipe off any contaminants.

- Nozzle Buildup: Over time, residue from previous prints can accumulate inside the nozzle. This is especially true for filaments with additives, like wood-filled or carbon fiber filaments. Regular cleaning with a nozzle cleaning kit (needles, brushes, etc.) is essential.

Okay, so you know what *causes* the problem, what do you *do* about it? Don’t worry – you’ve got options!

The Declogging Toolkit: What You Need

- Cold Pulls: Heat up the hot end to your filament’s printing temperature, then let it cool down to around 90°C (for PLA). Manually pull the filament out of the extruder. The solidified plug should bring any debris with it. Repeat until the filament comes out clean.

- Nozzle Cleaning Needles: Heat up the hot end and carefully insert a thin cleaning needle into the nozzle to dislodge any stubborn clogs. Be gentle – you don’t want to damage the nozzle!

- Acetone Bath (for ABS): Remove the nozzle and soak it in acetone to dissolve any ABS residue. Be careful when handling acetone, as it is flammable and can damage some materials.

- Nozzle Replacement: Sometimes, a clog is too persistent, or the nozzle is simply worn out. Replacing the nozzle is an easy solution. They’re relatively inexpensive.

Clogs are annoying, no doubt. But with a little preventative maintenance and the right tools, you can keep your filament flowing smoothly. Let’s move on to another crucial area: material properties.

Material Matters: Understanding Filament Properties

PLA, ABS, PETG, TPU… it can feel like alphabet soup! Each 3D printing material possesses unique properties that affect its printability and suitability for different applications. Ignoring these differences is like trying to bake a cake with motor oil – it just won’t work.

- PLA (Polylactic Acid): PLA is the go-to material for beginners. It’s easy to print, biodegradable, and produces parts with a smooth surface finish. However, it’s not very heat-resistant and can warp in high-temperature environments.

- ABS (Acrylonitrile Butadiene Styrene): ABS is stronger and more heat-resistant than PLA, making it suitable for functional parts. However, it requires higher printing temperatures and is prone to warping and fumes, so ventilation is a must.

- PETG (Polyethylene Terephthalate Glycol-modified): PETG combines the best of both worlds. It’s relatively easy to print like PLA but offers better strength and heat resistance. It’s a great all-around material.

- TPU (Thermoplastic Polyurethane): TPU is a flexible material, perfect for printing phone cases, gaskets, and other parts that need to bend. However, it can be challenging to print, as it tends to stretch and buckle.

Choosing the right material for your project is critical. Consider its strength, flexibility, heat resistance, and ease of printing. Don’t be afraid to experiment and find what works best for your printer and application. Speaking of making things work…

Fine-Tuning Your Feed: Optimizing Filament Guides

Filament guides play a crucial role in ensuring smooth and reliable filament feeding. These guides direct the filament from the spool to the extruder, preventing tangles, kinks, and friction. A well-designed filament guide can significantly improve your print quality and reduce the risk of failures.

Why Bother with a Guide?

- Reduced Friction: Guides minimize friction between the filament and the printer frame or other components. This ensures a consistent feed rate and prevents the extruder motor from working too hard.

- Tangle Prevention: By keeping the filament properly aligned, guides prevent it from tangling or knotting on the spool or along its path to the extruder.

- Improved Print Quality: A smooth, consistent filament feed translates to more accurate and reliable prints. You’ll see fewer layer inconsistencies and gaps.

Filament guides come in all shapes and sizes, from simple printed brackets to elaborate roller systems. Some printers come with built-in guides, while others require you to add them yourself. You can find tons of printable designs on sites like Thingiverse for nearly every model. Which, truthfully, is rad!

DIY Guide: Making Your Own

For some printers (and budgets!) a DIY solution can be perfect! Here’s what you need to consider:

- Simple Brackets: These are the easiest to make. Print or fabricate a simple bracket that attaches to the printer frame and guides the filament.

- Roller Guides: These guides use bearings or rollers to reduce friction. You can buy pre-made roller guides or design and print your own.

- Flexible Tubing: Use a length of flexible PTFE tubing to guide the filament. This is especially useful for printers with bowden extruders, where the filament travels a long distance to the hot end.

The goal is to create a smooth, low-friction path for the filament. Experiment with different designs and materials to find what works best for your setup. Now, let’s talk about dealing with moisture, because that *definitely* matters.

Battling the Damp: Combating Moisture Absorption

Here’s a thing you might not always consider: Filament is hygroscopic; which means it absorbs moisture from the air. And moist filament is a recipe for disaster.

When you heat moist filament in the hot end, the water turns to steam, creating bubbles and inconsistent extrusion. This can lead to stringing, poor layer adhesion, and weak parts. Think of it like popping popcorn – except instead of a tasty snack, you get a ruined print.

Spotting the Signs of Moisture

- Popping and Crackling: You might hear a faint popping or crackling sound as the filament is extruded. This is the sound of the moisture turning to steam.

- Stringing and Blobs: Moist filament tends to string and blob excessively. This is because the steam disrupts the flow of the plastic.

- Weak Parts: Parts printed with moist filament are often weaker and more brittle. The steam creates voids and weakens the layer bonds.

Don’t ignore these symptoms! You can often feel the change in the filament itself. So what do you *do*?!

Drying Things Out: Methods for Removing Moisture

- Filament Dryers: These are specialized devices that heat the filament to a specific temperature, driving out the moisture. Filament dryers can range from the cheap to the incredibly expensive.

- Oven Drying: You can dry filament in a conventional oven, but you need to be *very* careful not to overheat it. Set the oven to the lowest possible temperature (around 50°C) and monitor it closely.

- Desiccant Storage: Store your filament in airtight containers with desiccant packs. The desiccant will absorb any moisture that gets into the container.

If you live in a humid climate, drying your filament is a must. It may feel like extra work, but the results are worth it. Dry filament prints better, produces stronger parts, and saves you from wasting time and material on failed prints. Okay, let’s talk about dealing with those more ‘exotic’ filaments now!

Exotic Encounters: Printing with Specialty Filaments

Once you’ve mastered the basics, you might want to venture into the world of specialty filaments. These materials offer unique properties and aesthetics, but they also come with their own set of challenges. Carbon fiber, wood-filled, metal-filled, glow-in-the-dark… the possibilities are endless. It feels like you’re just opening up new possibilities!

Here’s the thing: just because you *can* print it doesn’t mean it’ll be easy:

Carbon Fiber Composites: Strength and Stiffness

Carbon fiber filaments are infused with tiny carbon fibers, making them incredibly strong and stiff. They’re ideal for printing parts that need to withstand high loads. However, they’re abrasive and can quickly wear out standard brass nozzles. You’ll need a hardened steel or ruby nozzle to print carbon fiber filaments reliably. You also need to adjust temperatures!

Wood-Filled Filaments: Natural Aesthetics

Wood-filled filaments contain wood particles, giving your prints a natural wood-like appearance. They can be stained, sanded, and finished like real wood. However, they tend to clog nozzles more easily than standard filaments, so you’ll need a larger nozzle (0.5mm or greater) and careful temperature control. These are mostly aesthetic uses, but can be super cool for art projects!

Metal-Filled Filaments: Heavy and Conductive

Metal-filled filaments contain metal particles, giving your prints a metallic look and feel. They’re much heavier than standard filaments and can even be polished to reveal the metal particles. However, they’re also very abrasive and require a hardened steel nozzle. They are *also* expensive!

Specialty filaments can open up a wide range of creative possibilities. But don’t expect them to be as easy to print as PLA or ABS. Be prepared to experiment with settings, nozzle types, and printing techniques. It can be a lot of fun IF you have the patience to invest! Finally, what about when things *just* go wrong?

When Things Go off the Rails: Advanced Troubleshooting

Sometimes, despite your best efforts, things just go wrong. Parts warp, layers separate, or the printer throws an error message. It’s frustrating, but don’t give up! Most 3D printing problems can be solved with a little troubleshooting. So what actions can you take?

- Warping: This is when the corners of your print lift off the build plate. It’s caused by uneven cooling and shrinkage. To prevent warping, use a heated bed, enclose the printer, and apply an adhesive like glue stick or hairspray to the build plate.

- Layer Delamination: This is when the layers of your print separate. It’s caused by poor layer adhesion, which can be due to low printing temperatures, insufficient cooling, or moist filament. Increase the printing temperature, reduce the cooling fan speed, and dry your filament.

- Error Messages: Pay attention to error messages! They often provide valuable clues about what’s going wrong. Consult your printer’s manual or search online for solutions to specific error codes.

One analogy might be useful: think of your printer like a car. Regular maintenance, proper settings, and a little troubleshooting can keep it running smoothly. Don’t be afraid to tinker, experiment, and learn from your mistakes. 3D printing is a journey, not a destination.

Ultimately, the most important thing with 3D printing is to have fun. Embrace the challenges, celebrate the successes, and never stop learning. With a little patience and persistence, you’ll be amazed at what you can create. Remember, every failed print is just a stepping stone on the path to mastery!

Conclusion: Mastering Materials and Guides

Alright, you know what? Whew! We’ve covered a lot of ground. From preventing filament tangles to printing with exotic plastics, you’re now armed with the knowledge to tackle common 3D printing issues. Remember, it’s about understanding your materials, optimizing your setup, and learning from experience. It does get easier!

3D printing isn’t just a technology; it’s a craft. It’s about experimenting, innovating, and bringing your ideas to life. So go forth, print with confidence, and don’t be afraid to push the boundaries. The only limit is your imagination.

Happy printing!

Simplify3D Troubleshooting Guide

All3DP Troubleshooting Guide

Frequently Asked Questions

DISCLAIMER

3D printing involves working with machinery that can be potentially dangerous. Always follow the manufacturer’s safety instructions when operating your printer. Wear appropriate protective gear, such as eye protection, when performing maintenance or repairs. Keep children and pets away from the printer while it is in operation. If you are not comfortable working with machinery, seek professional assistance.

The information provided in this article is for general guidance only. While we strive to provide accurate and up-to-date information, 3D printing technology is constantly evolving. Always consult with the manufacturer’s documentation and seek expert advice when needed. The author and publisher are not responsible for any damages or injuries resulting from the use of this information.

Categories

- 3D Printer (517)

- Automatic Mugs (426)

- Cleaning Appliances (504)

- Electric Bikes (214)

- Electric Scooters (456)

- Electronic Gadgets (183)

Recent Comments

Archives

Product Gallery

-

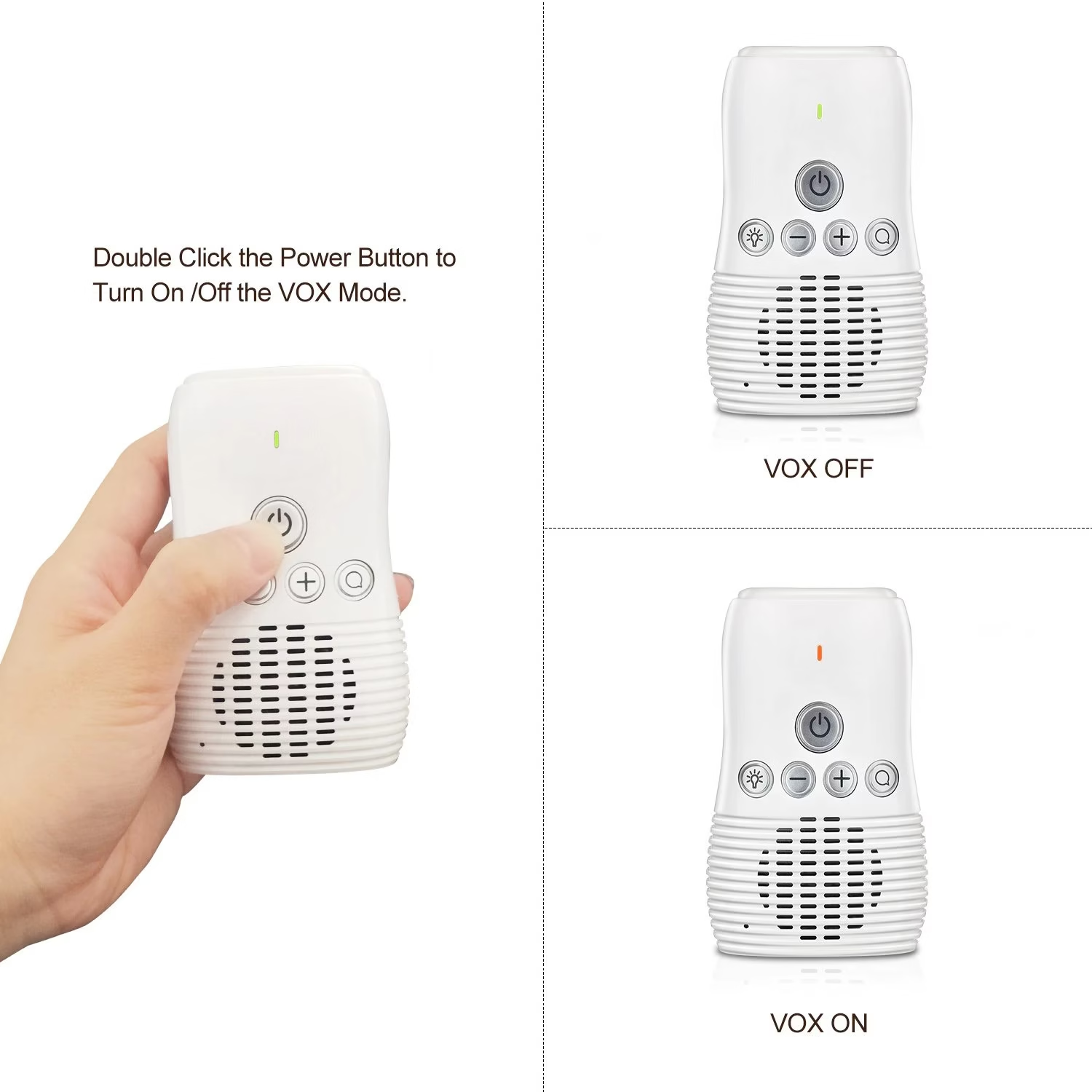

2.4Ghz Wireless Baby Monitor Small Portable Audio Baby Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 3.83 out of 5$35.00

2.4Ghz Wireless Baby Monitor Small Portable Audio Baby Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 3.83 out of 5$35.00 -

ABM01 2.4GHz Wireless Baby Monitor Audio Small Portable Babyphone Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 5.00 out of 5$44.00

ABM01 2.4GHz Wireless Baby Monitor Audio Small Portable Babyphone Monitor Two-way Audio Function Intercom Rechargeable Battery

Rated 5.00 out of 5$44.00 -

4.3 inch video baby monitor with 2 Cameras Pan Tilt Zoom,3000mAh Battery,Two-way Talk,Night Vision,Temperature,Feeding Reminder

$140.00 – $143.00Price range: $140.00 through $143.00

4.3 inch video baby monitor with 2 Cameras Pan Tilt Zoom,3000mAh Battery,Two-way Talk,Night Vision,Temperature,Feeding Reminder

$140.00 – $143.00Price range: $140.00 through $143.00

Robot Vacuums

Robot Vacuums Steam Cleaner

Steam Cleaner Window Robots

Window Robots

Self Stirring Mugs

Self Stirring Mugs Self Heating Mugs

Self Heating Mugs

Air Purifier

Air Purifier Dehumidifier

Dehumidifier Diffuser

Diffuser Humidifier

Humidifier

Panoramic Camera

Panoramic Camera Solar Camera

Solar Camera Window Door Sensor

Window Door Sensor Baby Monitor

Baby Monitor Small Cameras

Small Cameras

Electric Bike

Electric Bike Electric Bike Motor

Electric Bike Motor Electric Scooter

Electric Scooter Electric Skateboard

Electric Skateboard Hoverboard

Hoverboard

3D Printers

3D Printers 3D Printer Filament

3D Printer Filament